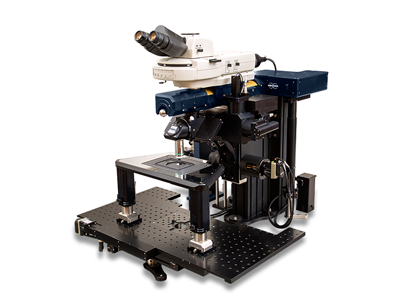

System Capabilities

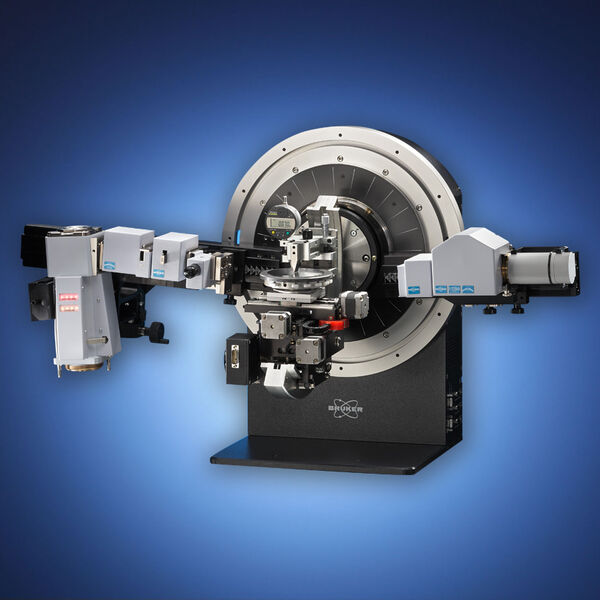

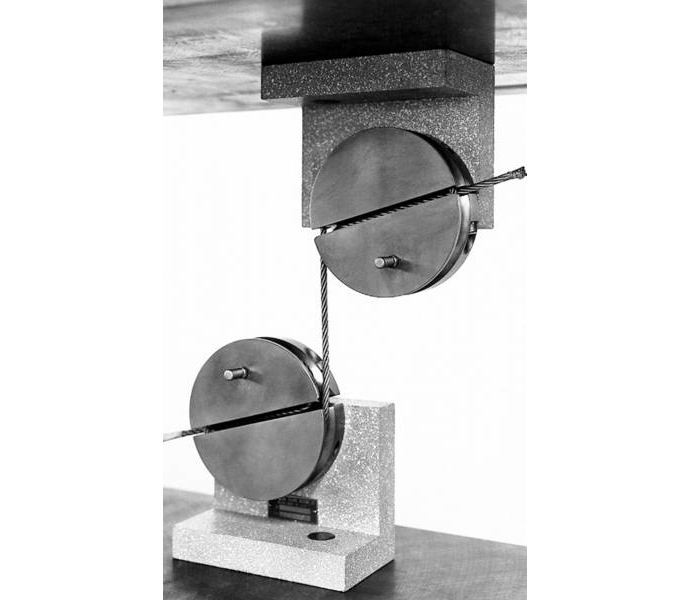

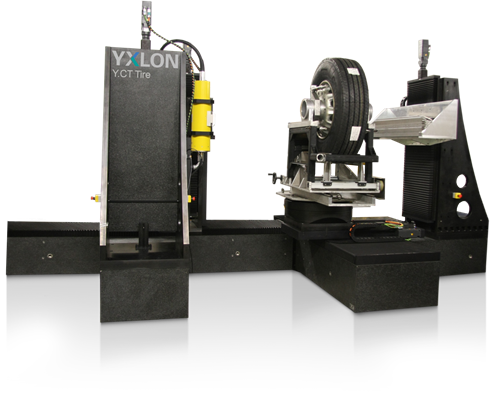

CT Tire computed tomography (CT) system brings modern CT to the tire industry. Specially developed for tire inspection, the system provides three-dimensional views that had not been obtainable until now. For example, individual wires in the belt plies are easily identifiable and can be measured in terms of their thickness, position and spacing. In special applications, a distinction can be made between individual rubber compounds.

CT Tire supports:

- Full tire scans for tires with an outer diameter up to 1200 mm in Scan Field Extension mode (1500 mm in Translate-Rotate mode)

- Section scans and scans of the contact area with tire widths of up to 650 mm

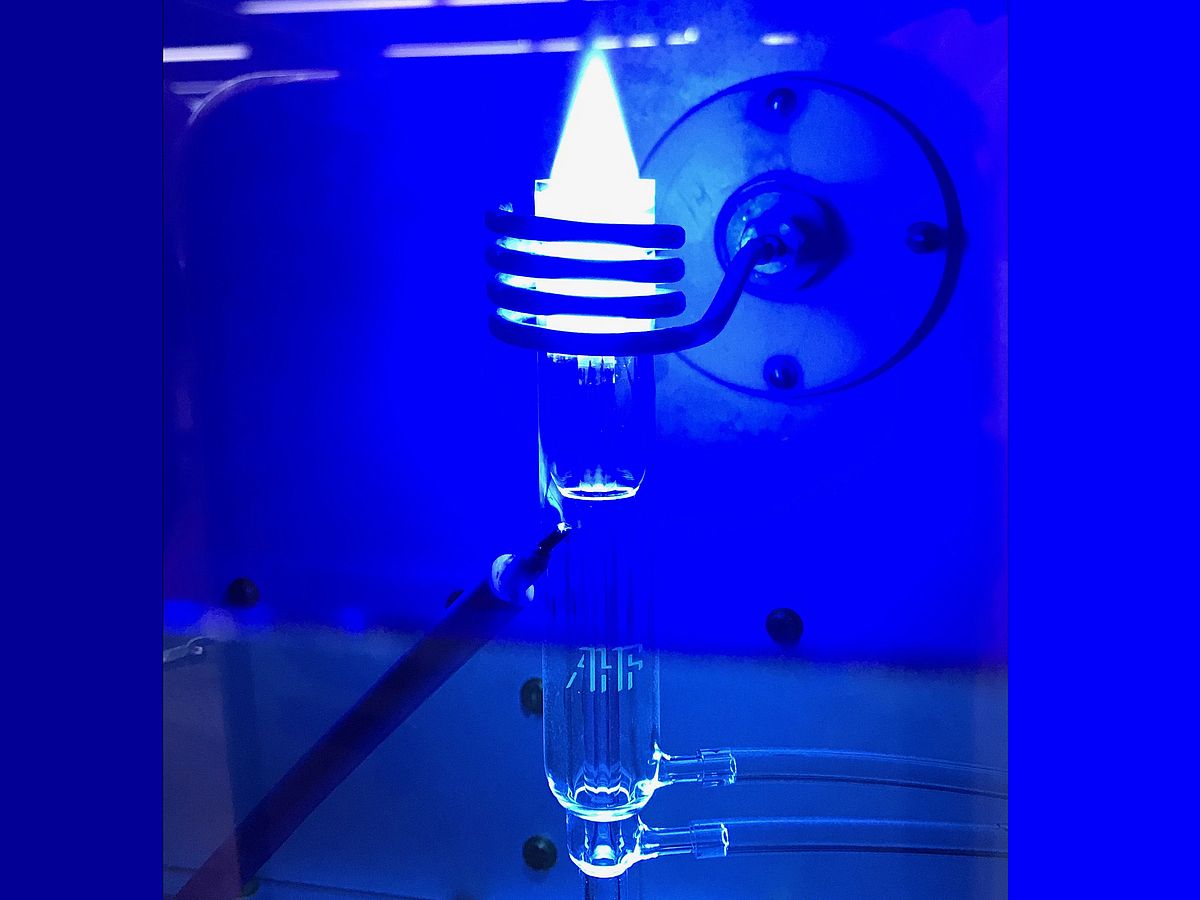

The system can be configured with a 600 kV X-ray tube or a linear accelerator, depending on the application. The 1000 mm Line Detector Array (LDA) provides outstanding image quality over a wide inspection envelope.

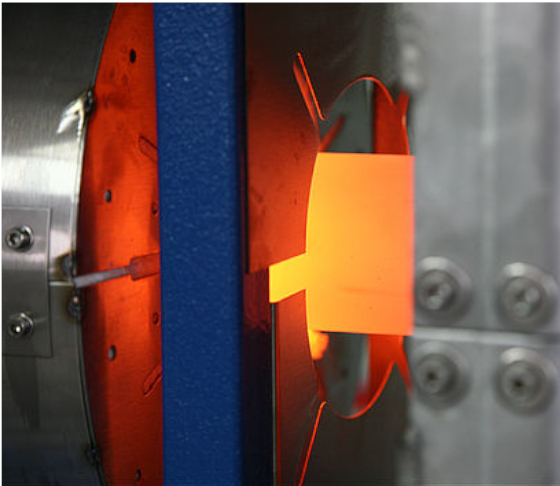

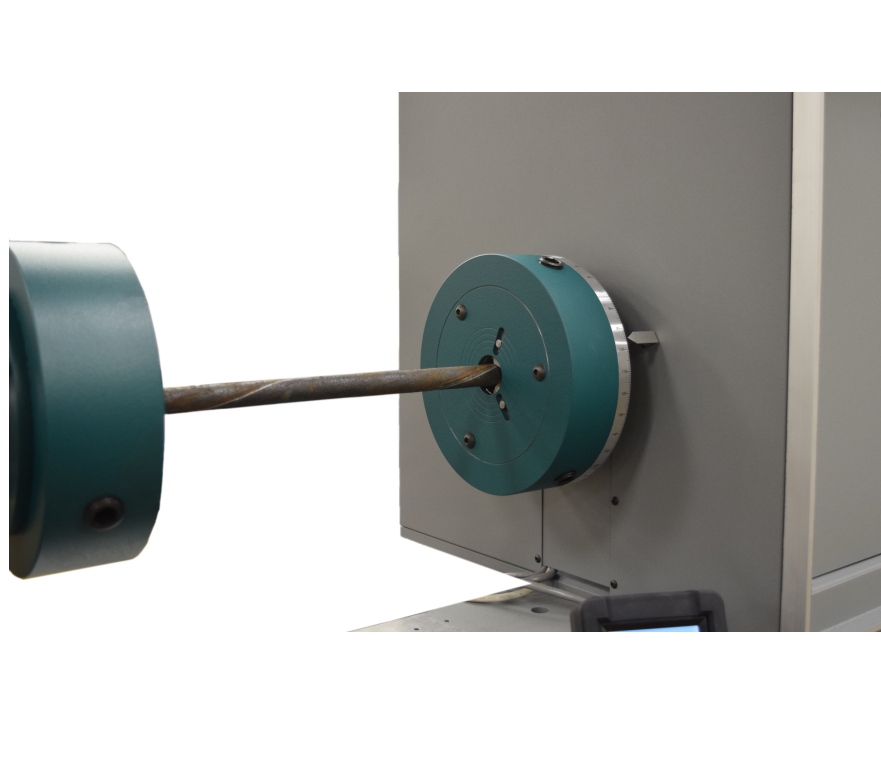

Object holders and manipulators have been designed for tire applications. Realistic load situations can be applied using the tire constraining unit, which allows examining the impact of vertical and lateral loads on the inner structure and the seat of the tire on the wheel.

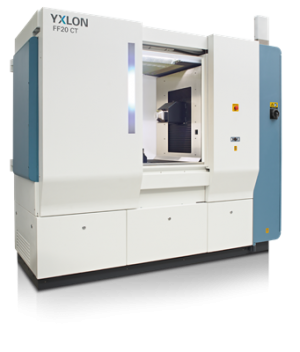

YXLON knows CT inside out. Our experts are ready to take on your problem and help find a solution for you.

YXLON CT software is installed on the system. It handles control, image acquisition, and 3D reconstruction. Additional software is available for viewing, editing and measuring the 3D data. The solution includes high performance PC hardware for efficient reconstruction of the scans.

Technical Data

| Attribute | Respective Value |

|---|---|

| Sample Diameter | Standard CT mode: Max. outer diameter 635 [mm] Scan field extension mode: Max. outer diameter 1200 [mm] Translate-Rotate-Mode: Max. outer diameter 1500 [mm] |

| Maximum Sample Weight | 1000 [kg] incl. fixture |

| X-ray Tube | 600 [kV] / 1500 [W] |

| Pixel Pitch | 250 [µm] |

| Spatial Resolution | 0,1 – 0,3 [mm] |

| Detector Type | Linear detectory array |

Đánh giá

Chưa có đánh giá nào.