System Capabilities

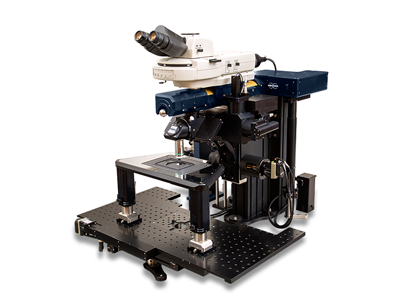

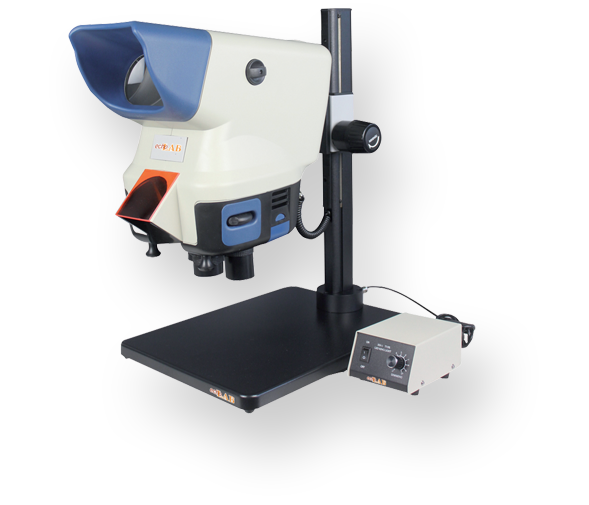

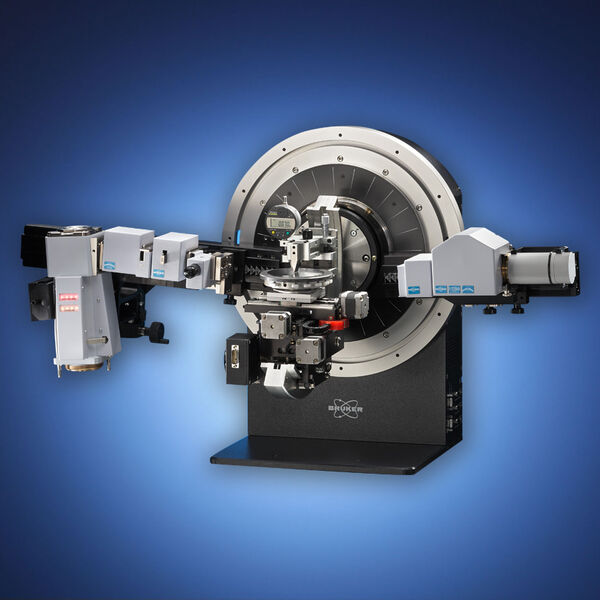

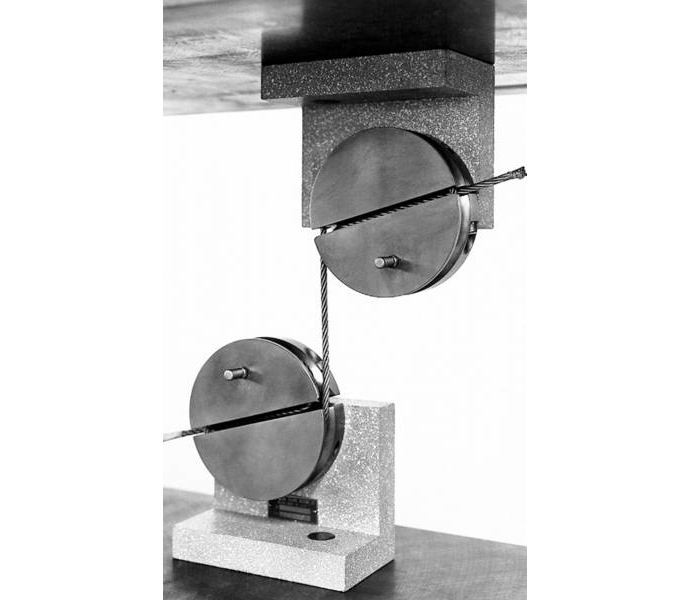

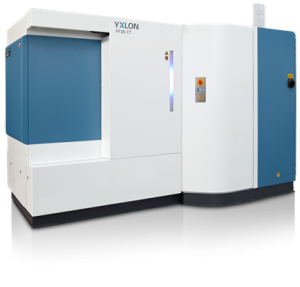

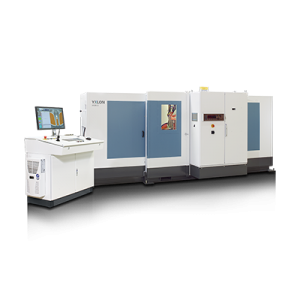

The MU56 TB robotic system is designed to test turbine blades for the aerospace sector. The system meets strict industry standards for safety critical parts including ASTM, MAI and Nadcap, and is DICONDE compliant. Manipulation of inspected parts is handled by an industrial robot, assuring exact positioning and fast cycle-times.

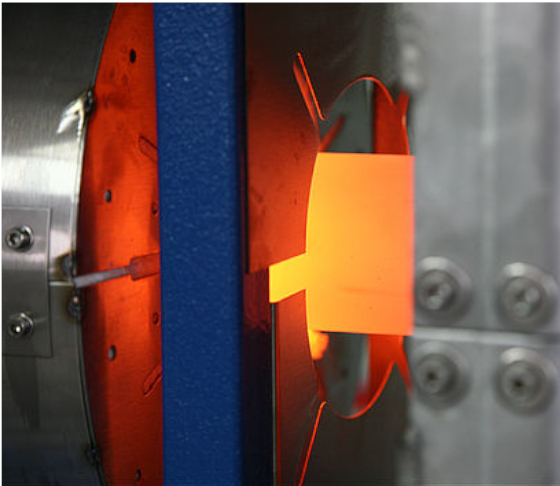

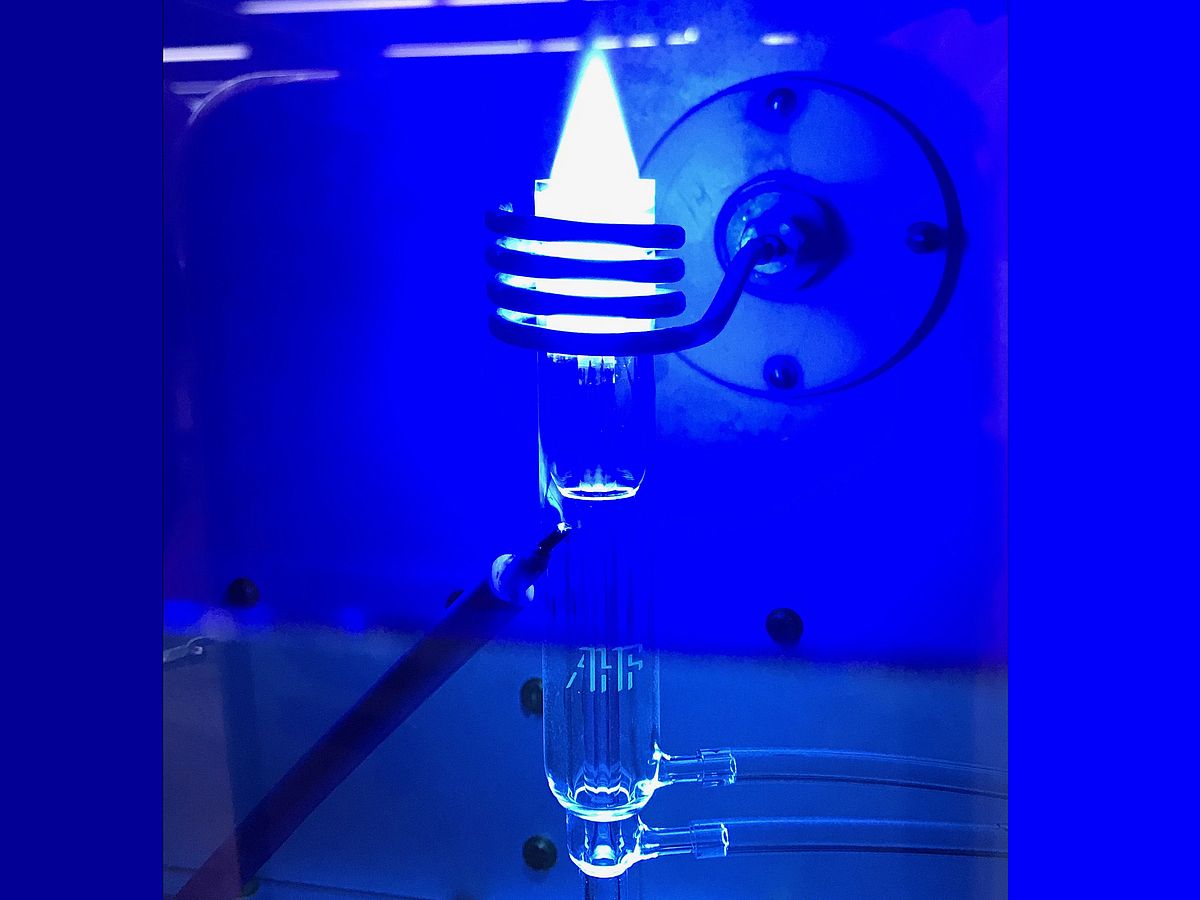

A variofocus X-ray tube and digital flat-panel detector combine to deliver superb image quality. And for applications requiring the highest resolution, the system’s variable focal spot size is indispensible. Together these features satisfy the preconditions to meet the high aerospace safety standards while at the same time increasing the efficiency and quality of your production process.

YXLON PXV5000 software is a core element of the MU56 TB and ensures fully automatic system control. Our IMAGE 3500 image processing software is easy to use and offers an array of image enhancement tools. Testing procedures like ASTM E2737 are automatically executed and can be easily documented, reported, and shared.

Maximize your efficiency with optional part/pallet type recognition systems and add review stations for image evaluation. Include our AdResult long-term archiving and statistics tool, one of a compliment of options designed to help optimize your inspection workflow.

The MU56 TB can be adapted to suit your special aerospace application needs.

Technical Data

| Attribute | Respective Value |

|---|---|

| Sample Dimensions | ~200 x 80 x 80 [mm] |

| Maximum Sample Weight | 2 [kg] |

| System Dimension | ~2300 x 2000 x 3000 [mm] |

| System Weight | 10000 [kg] |

| X-ray Tube | 225 [kV] |

| Detector Active Area | 1024 x 1024 [px] |

| Pixel Pitch | 200 [µm] |

| Bit Depth | 16 [bit] |

Đánh giá

Chưa có đánh giá nào.