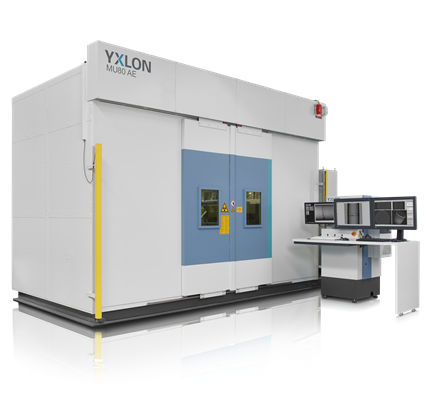

System Capabilities

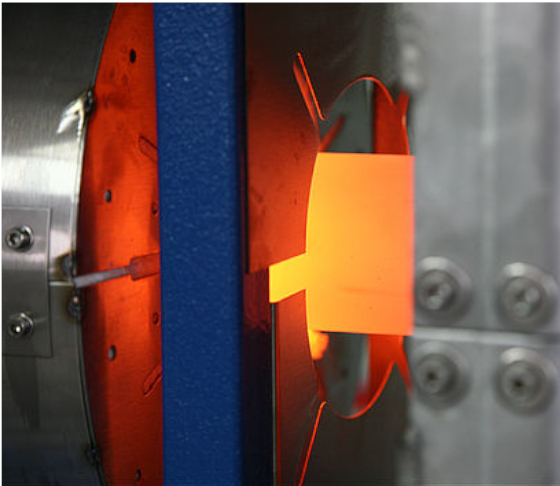

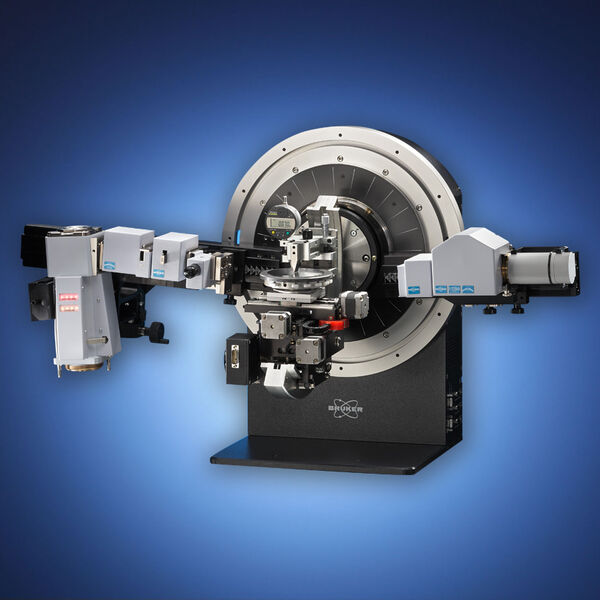

The MU80 AE is an excellent solution for sample evaluation, batch processing, and series inspection of large aerospace parts. This flexible industrial X-ray system has room to handle a maximum part size of 800 mm in diameter and 1500 mm in height and a part weight of up to 100 kg, using a motorized loading axis. A split door allows for short loading and unloading times and improves efficiency of inspection.

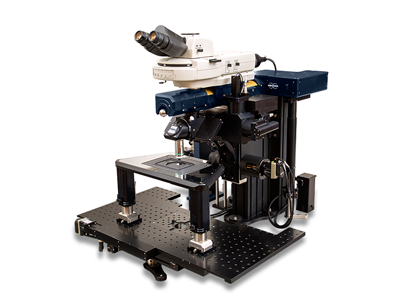

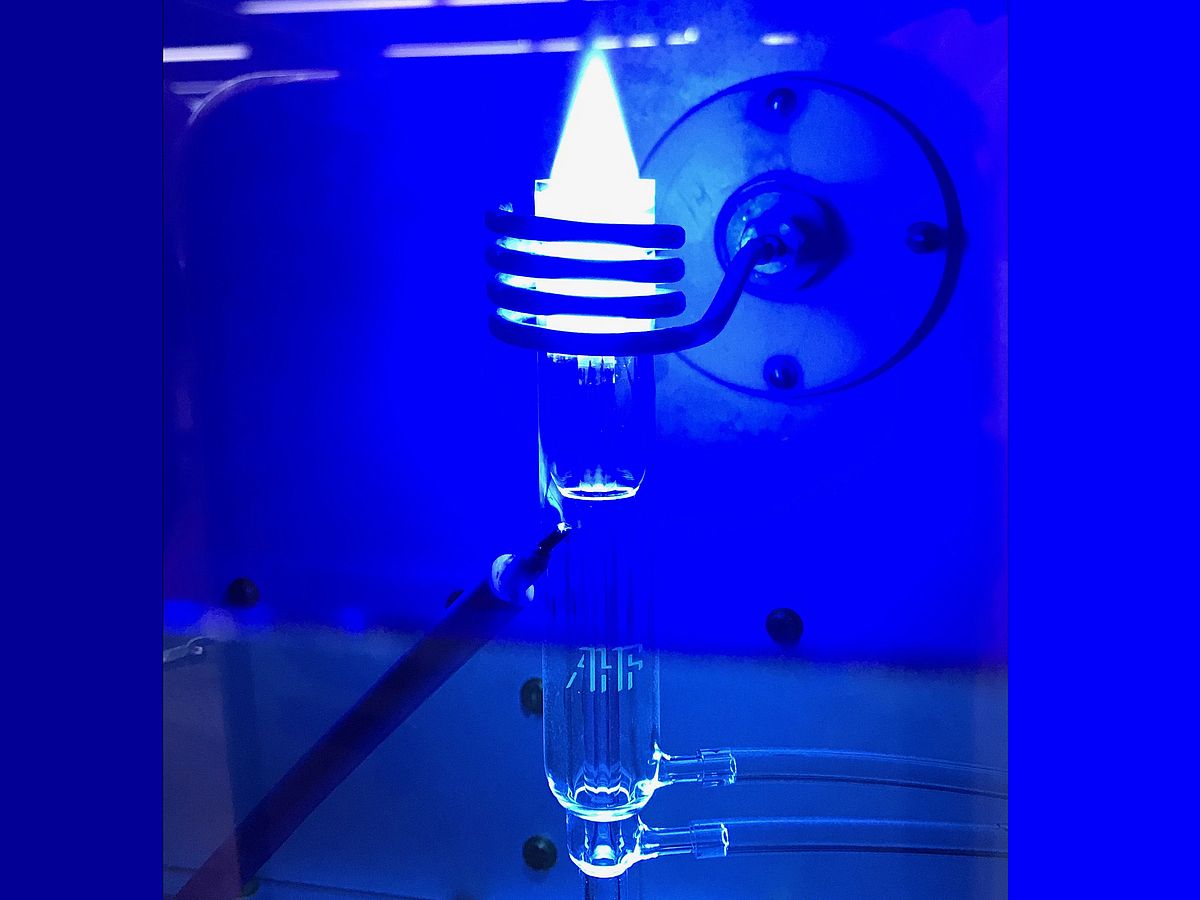

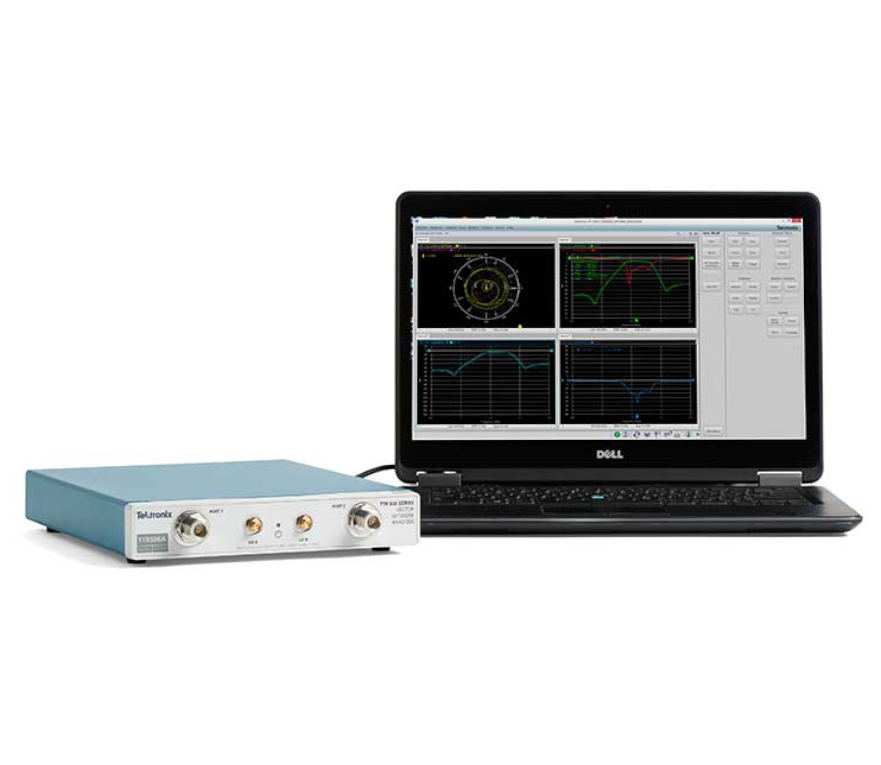

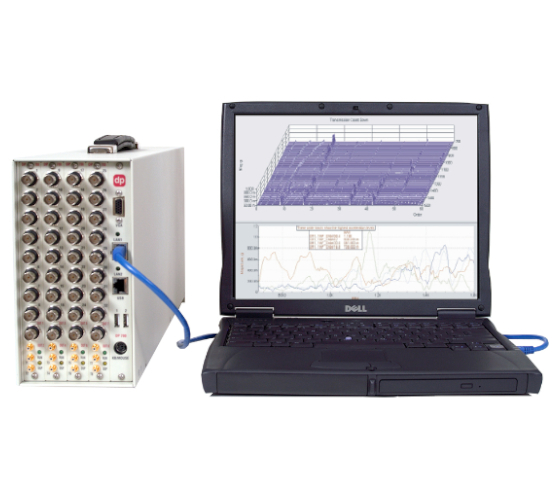

2D radiographic inspection with easy-to-program sequences can be paired with our computed tomography (CT scan) option, which allows for failure analysis in three-dimensional volume and slices. The FeinFocus X-ray tube and 16” cooled detector delivers high-resolution, high-contrast X-ray images and high quality CT scans and is supported by advanced software analysis for precise detection on the spot!

Automated inspection plans with multiple views can be conducted without human interaction. Just load and press the start button.

A spectrum of options further improve process efficiencies:

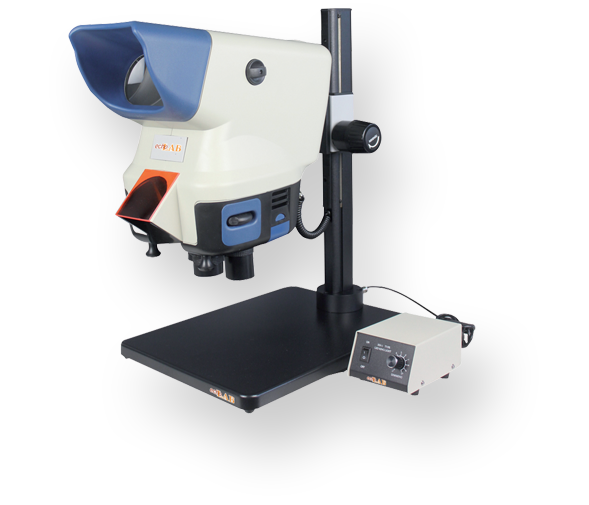

- Review station for efficient inspection workflow

- HeliExtend for CT of vertically elongated parts without stitching the image

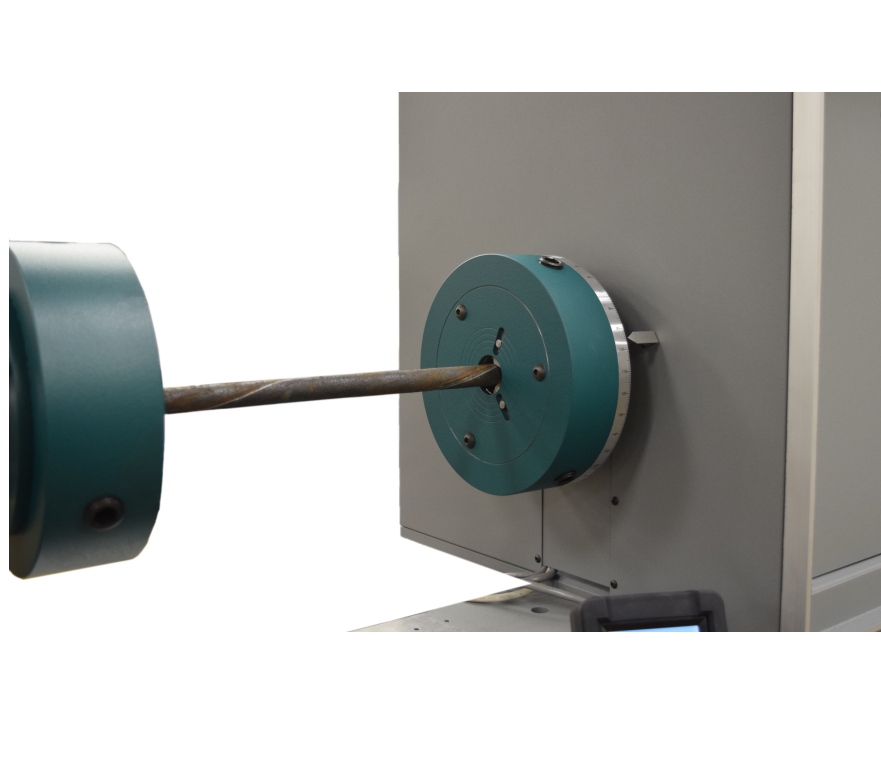

- Tilt axis +/- 60° specifically for the inspection of ducts and pipes

In order to ensure acceptable inspection quality of your safety-critical components, the MU80 AE complies with requirements of current aerospace industry standards such as MAI, Nadcap, ASTM, and DICONDE.

YXLON’s tube technology for long life and high system uptime is a prerequisite for repeatable, reliable results. MU80 AE is customizable to fulfill your special application needs.

Đánh giá

Chưa có đánh giá nào.