Standard options

- Different temperature controllers

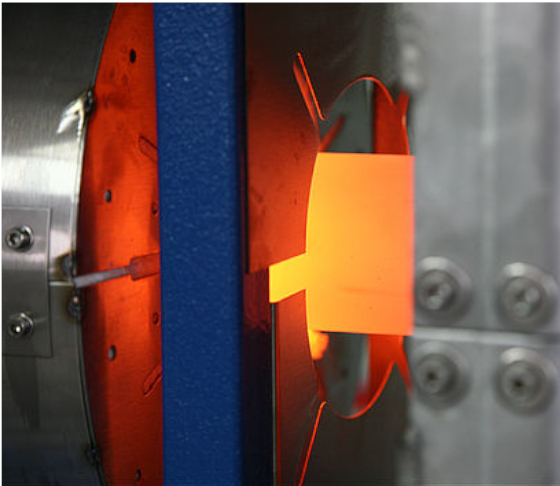

- Gassing unit for save operation when using flammable and explosive gases, burning-off device with flame supervision for save operation when using flammable and explosive gases

- Safety package for safe operation

- Gas warning system for safe operation when using flammable and explosive gases

- Insulation for hydrogen operation, energy saving when using gases with high heat conductivity

- Viewing glass for visual process control or additional pyrometer measuring

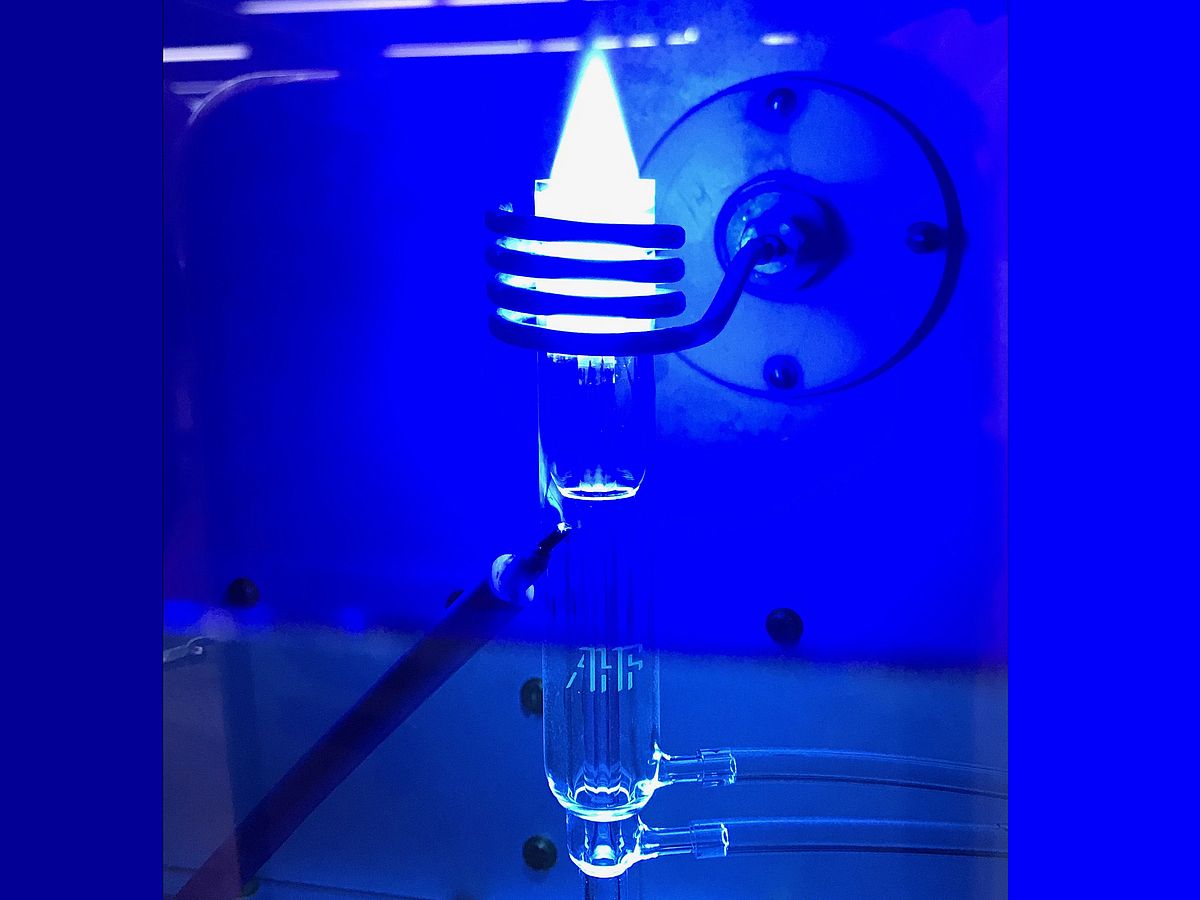

- Condensate trap for “dirty” processes such as debinding, pyrolysis

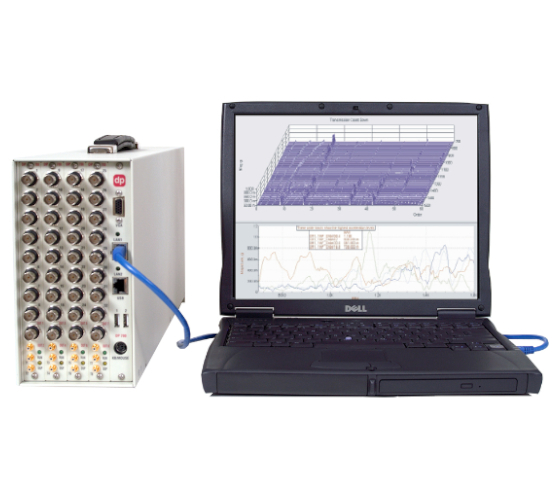

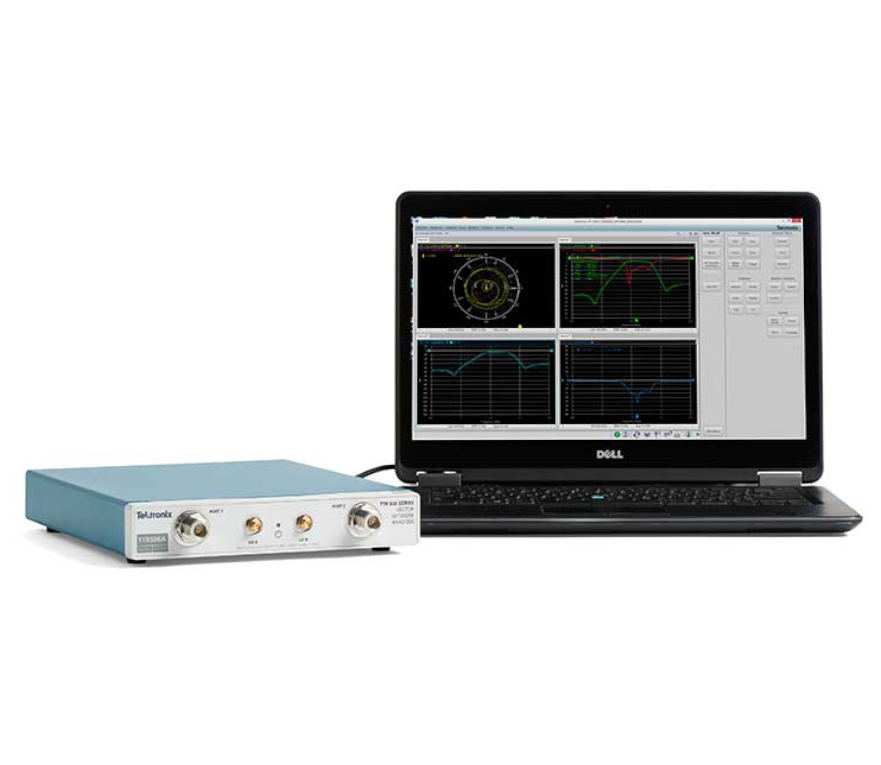

- Process guiding software for full control and documentation via PC

Other options

- Multi-zone-heating for best temperature accuracy

- Trailing thermocouples

- Gas recooling for fast cycles

- Bursting disc as safety component

- Temperature recorder

- Quick lock furnace door bottom

- Design according to ATEX guide lines

Technical data

Furnace housing

The protective gas and vacuum tight, from all sides reinforced inner housing is cooled by a fan to avoid outer wall temperatures of the housing of 180 °C, also during continuous operation.

The corresponding designed outer housing remains cool (max. 40 °C above room temperature).

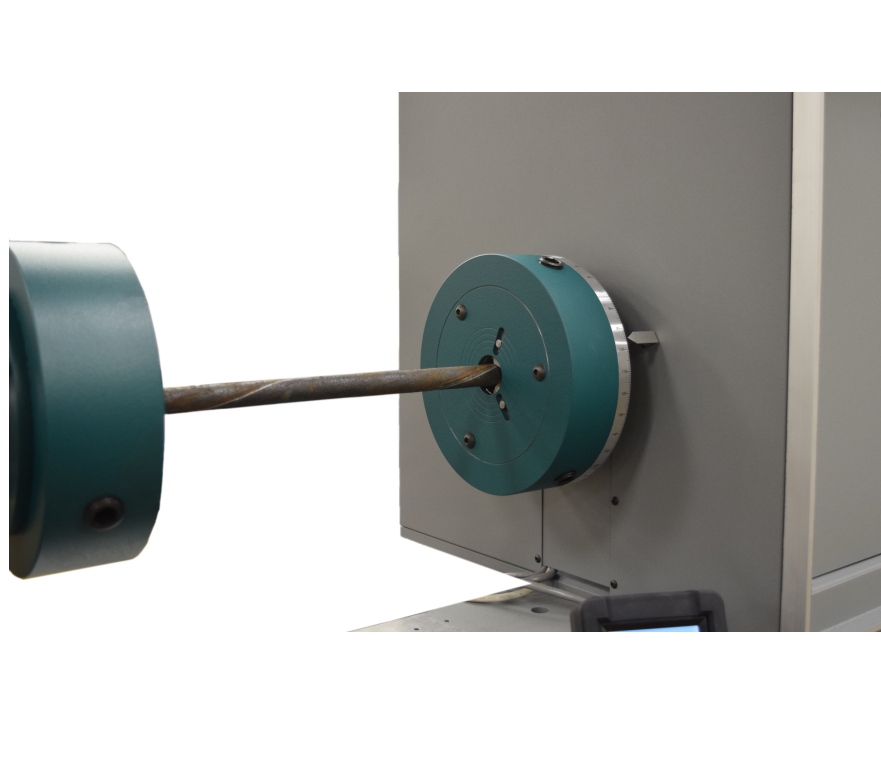

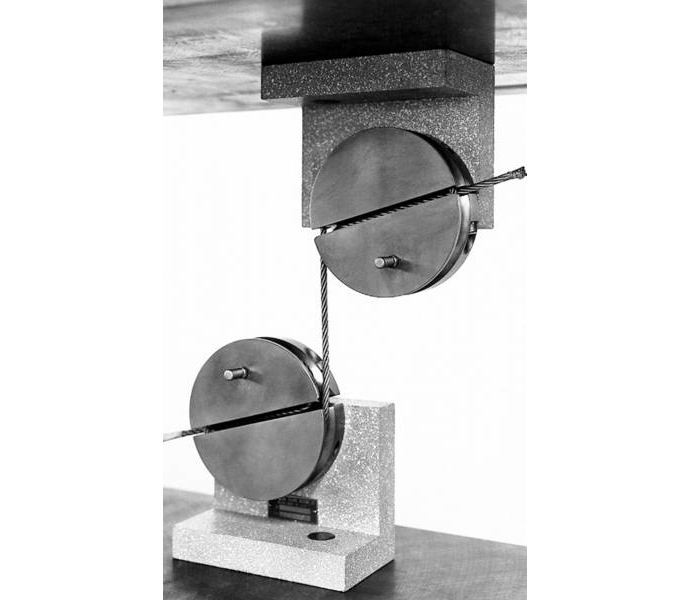

The furnace bottom with a special sealing can be automatically moved up and down with a mechanism and is guided via a strand guide section.

The protective gas respectively vacuum tight bottom door is designed as explosion door (pressure limit appr. 10 – 20 mbar) and intended with turn-locks with adjustable spring pressure resistors.

On the rear side of the furnace there are connection flanges for inlet and outlet of protective gas, vacuum and the thermocouple.

Door flange, connections for thermocouple and heating elements as well as gas outlet are water cooled.

Insulation

The inner housing is lined with high-quality insulation materials (graphite or high temperature bricks as well as PCW plates). Lightweight, low energy consumption materials enable extremely short heating up and cooling down times (brick insulation excluded).

Heating

The furnace is heated on four sides by replaceable MoSi2, Mo, W or graphite heating elements, which are operated by a 3-phase thyristor unit with phase-angle and a transformer. The heating element connections are led out on the furnace rear wall.

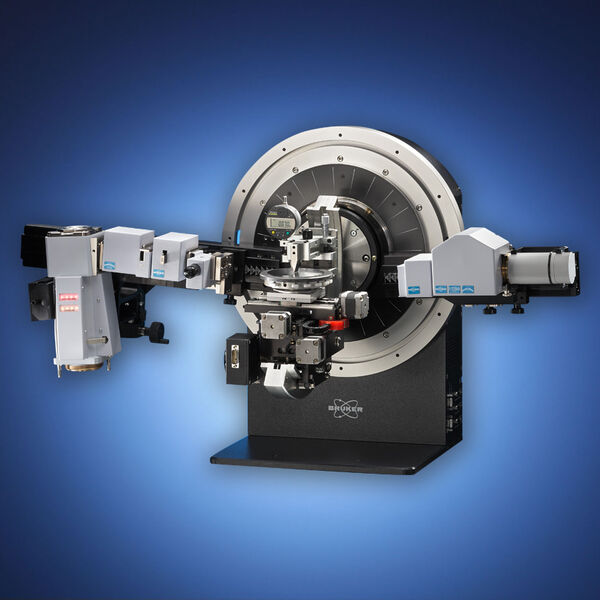

Lateral, appr. In the middle of the furnace (seen from the rear wall), there is a PtRh-Pt double thermocouple type S (type B/C) (accuracy: class 2 according to DIN IEC part 2), which measures the temperature. A thermoelement pair leads to the temperature controller, the other one to the safety controller. A pyrometer measuring is (optionally) carried out laterally or from the cover.

Switch and control unit

1 pc. Lockable safety controller for additional protection of heating and insulation

1 pc. 3-phase thyristor unit for phase-angle and current limitation

1 pc. pre-transformer

1 pc. Working hours counter

3 pcs. power indicator

PRODUCT PROPERTIES

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Furnace |

| Designs: | Bottom loader furnace, Chamber furnace |

| Temperature Max (°C): | 2400 |

| Heatings: | electrical |

| Heatingmethods: | resistance |

| Atmospheres: | Air, Controlled gas atmosphere, VThe most important characteristics

acuum |

| Applications: | annealing, bright annealing, graphitization/carbonisation, heat treatment, melting, reduction, remelting, sintering |

Reviews

There are no reviews yet.