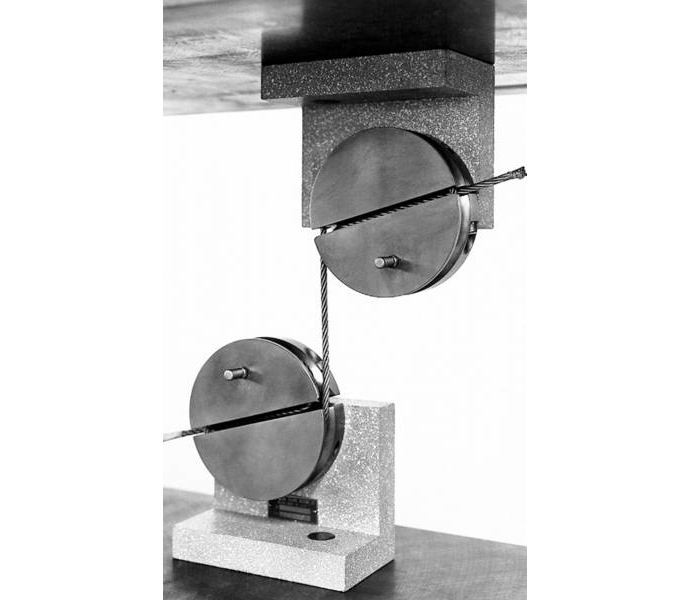

| Main Technical Data | |

| Basket capacity | 130 lt |

| Basket useful | dim. 614x500x425 (WxDxH) mm approx |

| Maximum basket load | 50 Kg |

| Chamber external | dim. 1252x2072x2844 (WxDxH) |

| Temperature range (measured at room temperature of 22°C, empty working space and nominal voltage): | • upper chamber +70/+220°C • lower chamber -80/+100°C |

| Temperature fluctuation: | ±1°C |

| Basket displacement speed | <10 sec. |

| Max load with MIL 883 test (15 min resetting time on specimen): | • 13 kg Ics distributed on 2 shelves with MIL 883 test D • 20 kg Ics distributed on 2 shelves with MIL 883 test C • 26 kg Ics distributed on 2 shelves with MIL 883 test B |

Reviews

There are no reviews yet.