HIGHLIGHTS

All interface options integrate with Horizon data analysis software

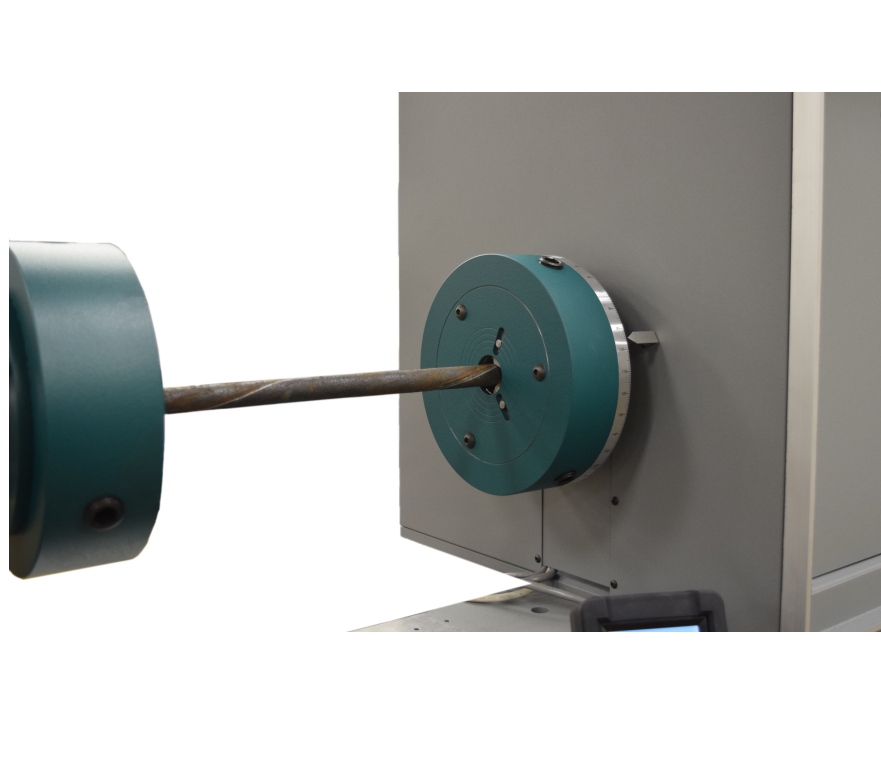

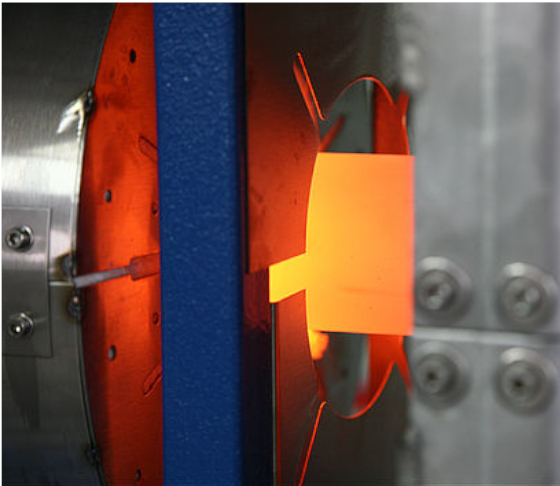

Suitable for tension, compression, flexure, shear and other tests to a maximum force of 150kN / 30,000 lbf

Built-in pneumatic distribution ports that provide local air supply to pneumatic grips

Meets or exceeds the requirements of national and international standard for materials testing systems

12 full-length T slots built into machine column to allow accessories to securely mounted to the test frame

Various system interface options available, from a familiar tethered handheld interface, a wireless Bluetooth interface panel, or virtual machine controller

| Value SI | ||

| 150ST | ||

| Tension Compression load capability | Yes | |

| Frame capacity | 150kN | |

| To frame capacity | |

| Floor or table mounting | Floor standing | |

| Test zones | 1 | |

| Number of columns | 2 | |

| Column material | Aluminium Extrusion | |

| Column finish | Anodise | |

| Column colour | Natural | |

| Base material | Mild Steel | |

| Base finish | Pre primed, top coat powder coat paint | |

| Base colour | TO Cool Grey Web # E6 30 27 | |

| Crosshead material | Mild Steel solid | |

| Croshead finish | Pre primed, top powder coat paint | |

| Crosshead colour | TO Green Web # 00 4C 45 | |

| Base cover | ABS recyclable | |

| Base cover colour | Cal Black Web # 11 18 20 | |

| Distance between columns | 656mm | |

| Max cross head travel | 1198mm | |

| Optional extension to cross head travel | 400mm | |

| Stiffness | 460kN/mm | |

| Height | 2323mm | |

| Width | 1205mm | |

| Depth | 700mm | |

| Weight | 954kg | |

| Force protection system | Yes digital | |

| Displacement protection system | Yes mechanical & user programmable | |

| Accessory fitting interface type | Female diameter | |

| Ball screw type | High precision low backlash | |

| Ball screw cover/protection | Yes | |

| Crosshead drive system | AC servo motor | |

| Feet material | Mild Steel with anchor bolt oprtion | |

| Feet adjustment & levelling | Yes provision for M20 jacking screw | |

| Reference rule to support cross head positioning | Yes | |

| T slots in columns for accessory mounting | 12 * M6/M8 | |

| Noise at full crosshead speed 2m radius | 42db |

| Spec parameter | Value SI | |

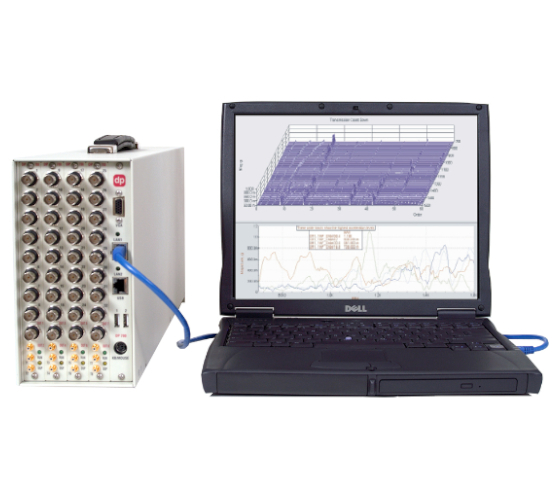

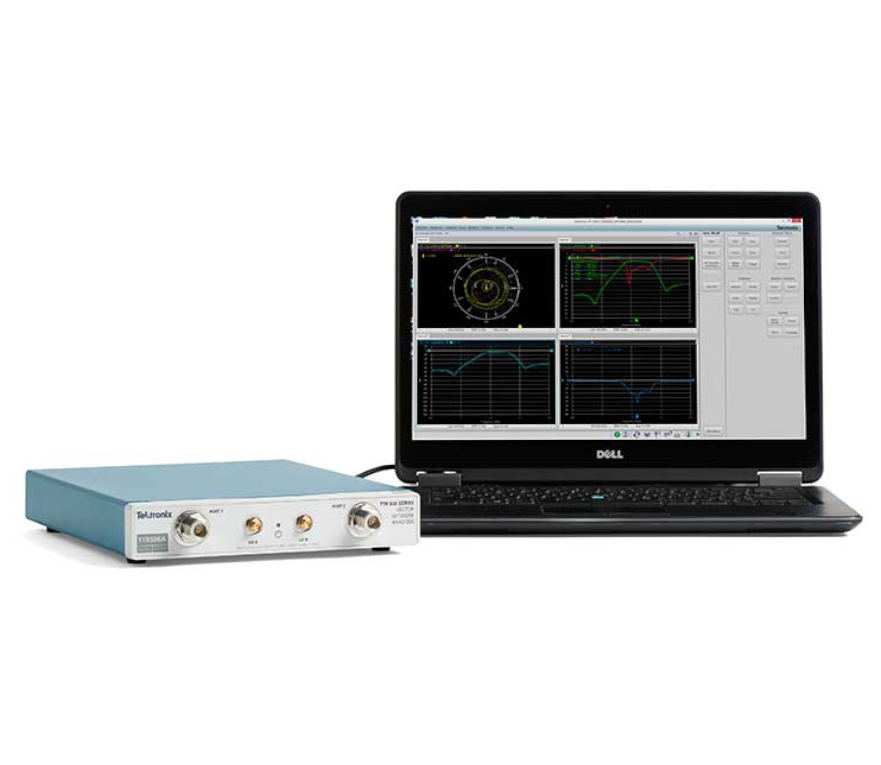

| Controller | Max data processing rate | 168 MHz |

| Data acquisition rate at PC | 1000 sps | |

| Number of instrument device connections external | 4 | |

| Number of instrument device connections internal | 3 | |

| Bluetooth enabled | v4.0 with A2DP, LE, EDR | |

| External PC connection | USB | |

| User interface connectivity | TO HMC, Proterm, Horizon | |

| Force | Force measuring device – type | Strain gauge based load cell |

| Load cells available | 25N 50N, 100N, 250N, 500N, 1kN, 2.5kN, 5kN, 10kN, 25kN, 50kN | |

| Resolution | 1 part in 8388608 | |

| Accuracy | +/-0.1% of applied force across load cell force range | |

| Range | 0.2% to 100% | |

| Calibration standard | ISO 7500-1 ASTM E4 | |

| Internal sampling rate | 1000sps | |

| Extension measurement | Resolution | 0.1um |

| Accuracy | +/-10um | |

| Range | +/- 217m | |

| Calibration standard | ISO 9513, ASTM E83 | |

| Internal sampling rate | 2.73ksps | |

| Position control | Test Speed | 0.001mm/min to 500 mm/min up to 20kN |

| 0.001mm/min to 250 mm/min up to 50kN | ||

| Resolution | 0.1um | |

| Accuracy | +/- 0.005% | |

| Return speed post test | 0.001mm/min to 500 mm/min | |

| Resolution | 0.1um | |

| Accuracy | +/- 0.005% | |

| Crosshead positioning speed | 0.001mm/min to 500 mm/min | |

| Resolution | 0.1um | |

| Accuracy | +/- 0.005% | |

| Return to zero function | Yes | |

| Power requirement | Supply voltage options | 110/240V |

| Frequency | 50/60Hz | |

| Current | ||

| Power | 2000W +/- 10% | |

| Atmosphere | Operating temperature | 10 to 40 degree C |

| Operating humidity | 10% to 90% non condensing | |

| Storage temperature | 10 to 69 degree C | |

| Storage humidity | 10% to 90% non condensing | |

| Warranty | 18 months |

Reviews

There are no reviews yet.