HIGHLIGHT

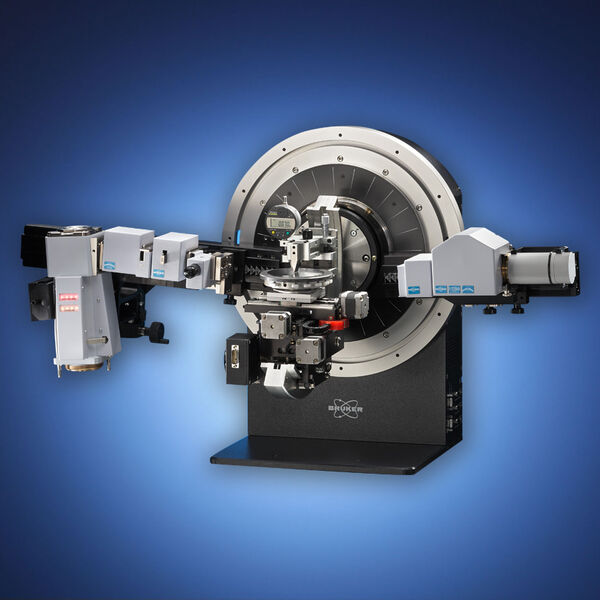

Scales – All FH7 models can test Micro-Vickers, Vickers, Knoop and Low Force Brinell scales but the FH7-2 adds Rockwell and Superficial Rockwell, while the FH7-3 increases Brinell testing capacity to 250kgf. In its ultimate configuration, the FH7 has fully automatic advanced co-ordinate pattern, weld pattern and free style testing of metallic and plastic parts in any common hardness scale.

Safety first/collision detection system – To ensure maximum user safety and protect the tester, all FH7 models have an advanced collision detection, warning and test head retraction system. This is triggered by any uncommon force on the turret and will stop and retract the test head in milliseconds, protecting the operator’s hands and indenters, objectives and workpieces.

Quick change stage and anvil post – As an alternative to the standard ultra-fast motorized CNC stages, there is the option to install larger T-slot stages, fixed stages and a number of anvils. To save time exchanging the nearly unlimited choice of stage and anvil options, the tester features the quick change accessories post, which allows tester reconfiguration in seconds.

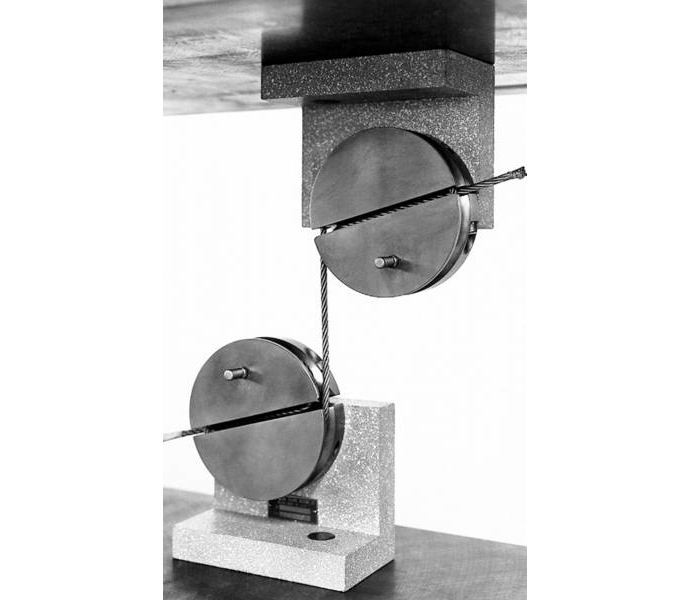

Unparalleled test force range – The servo-driven force actuator allows test forces from 10gf up to 250kgf, a capability unique to Tinius Olsen, which uses its own precision load cells and force control electronics. The load actuator is able to position the test head, with sub-micron accuracy, in any required position, and at unsurpassed speed, allowing for greater testing throughput.

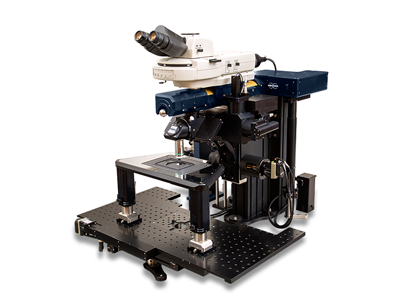

Advanced high speed turrets – The high speed, eight-position turret, is the first hardness tester to incorporate a standard built-in laser positioning systems. The turret also contains two HD cameras, with auto focus and optical zoom system, allowing stage (over) viewing at indenter position.

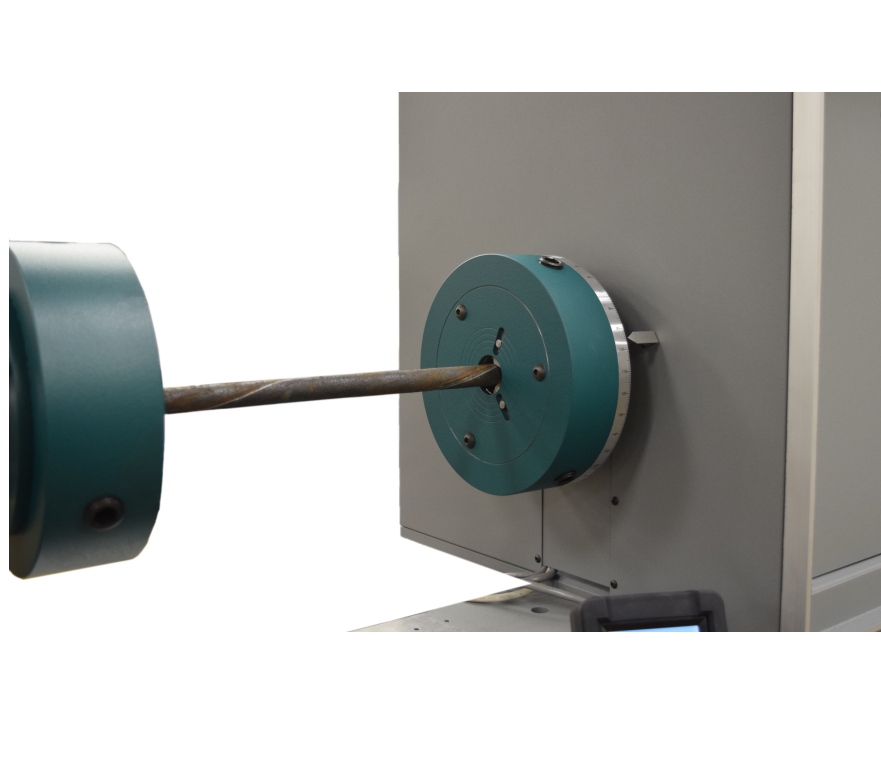

Clamping device – An integrated clamping device will firmly hold the workpiece against the anvil or test table while performing Rockwell or other depth measuring tests (optional).

| Hardness scale (model dependent) | (Micro-) Vickers, Knoop and Brinell, Rockwell and Superficial Rockwell |

| Load application | Load cell, force feedback, closed loop system |

| Load range | 10gf up to 250kgf |

| Motorized turret | Eight positions: two indenter, four objectives, overview camera, laser pointer; one position for 3-250kgf |

| Optical system | High definition, 5MP machine vision system |

| Objectives | 2.5x, 5x, 10x, 20x, 50x, 100x |

| Overview camera Camera 2 | 5MP optical ZOOM camera, field of view 50 x 37mm / 200 x 160mm |

| Electronic system | High performance embedded micro-system controller, MS Windows®, 15in full color industrial touchscreen, automatic and manual measurement |

| Test loads (depending on model) | 10gf, 15gf, 20gf, 25gf, 50gf, 100gf, 200gf, 300gf, 500gf, 1kgf, 1.25kgf, 2kgf, 2.5kgf, 3kgf, 4kgf, 5kgf, 6.25kgf, 7.8125kgf, 10kgf, 15kgf, 15.625kgf, 20kgf, 30kgf, 31.25kgf, 40kgf, 50kgf, 60kgf, 62.5kgf, 80kgf, 100kgf,120kgf, 125kgf, 150kgf, 187.5kgf, 250kgf |

| Vickers test range | HV0.010, HV0.015, HV0.020, HV0.025, HV0.050, HV0.1, HV0.2, HV0.3, HV0.5, HV1, HV2, HV2.5, HV3, HV4, HV5, HV10, HV20, HV25, HV30, HV40, HV50, HV100, HV120 |

| Brinell test range | HB1/1kgf, HB1/2.5kgf, HB1/5kgf, HB1/10kgf, HB1/30kgf; HB2.5/6.25kgf, HB2.5/15.625kgf, HB2.5/31.25kgf, HB2.5/62.5kgf, HB2.5/187.5; HB5/25kgf, HB5/62.5kgf, HB5/125, HB5/250; HB10/100, HB10/125, HB10/250 |

| Knoop | HK0.01, HK0.02, HK0.025, HK0.05, HK0.1, HK0.2, HK0.3, HK0.5, HK1, HK2, HK5, HK10, HK20, HK30, HK50 |

| Test cycles | Automatic and manual |

| Standards | Complies to or exceeds, ISO, ASTM, JIS (Nadcap) standards |

| Test force accuracy | <0.5% for test force 100g to 62.5kg <1% for test force below 100g |

| Display resolution | 0.1 HV, HK, 0.5 HB |

| Hardness conversion | Rockwell, Rockwell Superficial, Brinell, Leeb and Tensile |

| Statistics | Total test, max, min, average, range, standard deviation, all in real time after each test |

| Data storage capacity | Dual SSD 80GB, RAID system |

| Connectivity | Two USB ports, RJ45 Ethernet LAN, W-LAN, RS232, Bluetooth; five-axis CNC and motorized X-Y stage connector |

| Dwell time setting | 0-99 seconds, user defined |

| Standard Motorized CNC XY stage dimensions | Stage 400 x 225mm, Travel: X axis 220mm, Y axis 120mm, Repeatability 0.002mm |

| Operating temperature | 10-35o C, non-condensing |

| Humidity | 10-90% non-condensing |

| Machine dimensions | 695 x 425 x 1100mm |

| Machine weight | 180kg |

| Power consumption | 100W |

| Power supply | 100VAC to 240VAC, 50/60Hz, single phase |

| FH-7-1 | 10g-62.5kgf | Vickers, Micro-Vickers, Knoop, Low Force Brinell, KiC |

| FH-7-2 | 10g-150kgf | Vickers, Micro-Vickers, Knoop, Low Force Brinell, KiC, Rockwell, Superficial Rockwell |

| FH-7-3 | 10g-250kgf | Vickers, Micro Vickers, Knoop, Low Force Brinell, Brinell, Rockwell, Superficial Rockwell KiC, HVT, HBT, ISO 2039 1/2 |

Reviews

There are no reviews yet.