Options

- Additional output adapter

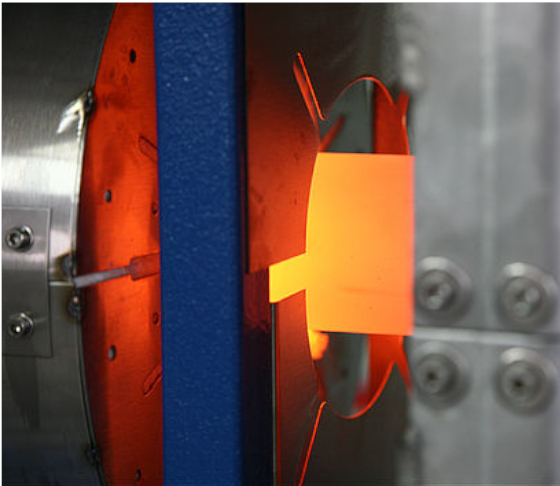

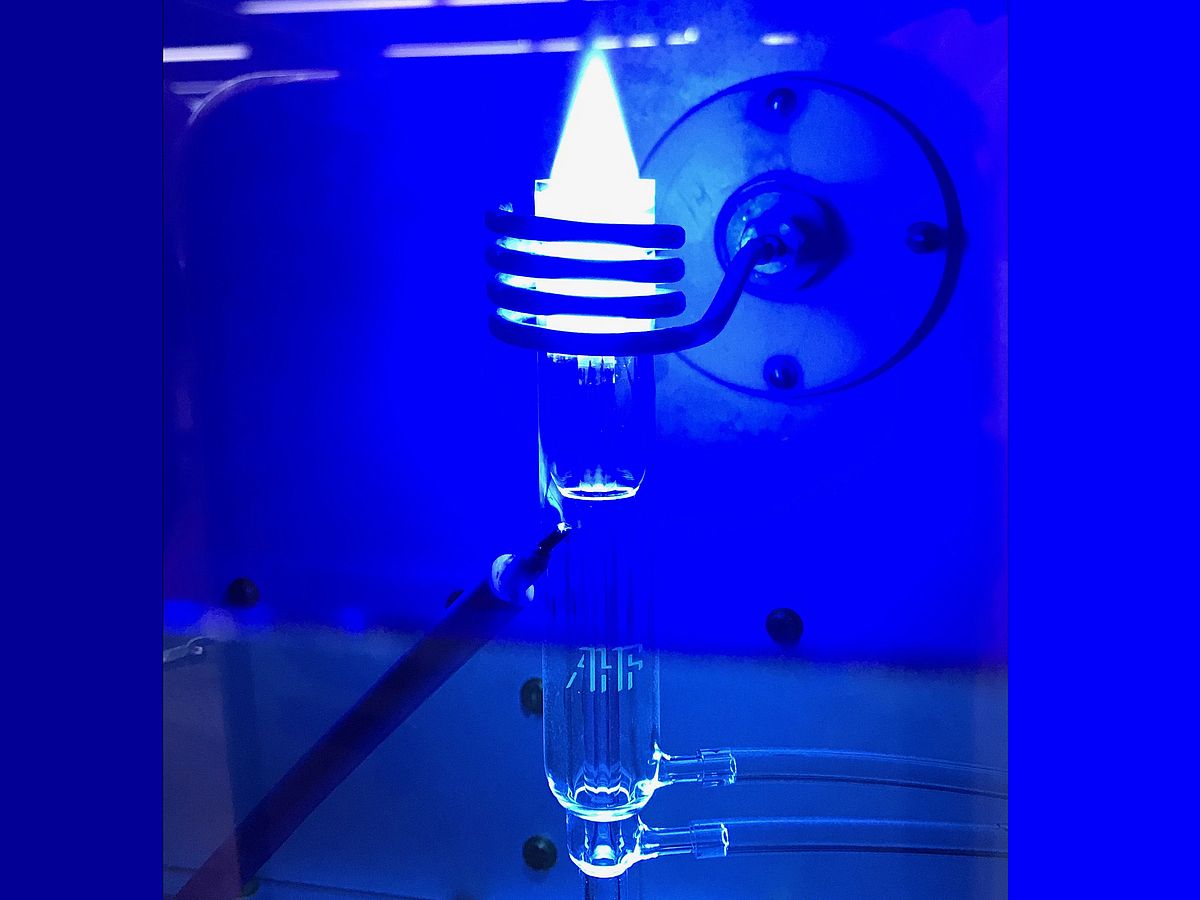

- Induction coil according to client requirements

- Temperature control with pyrometer

- Safety temperature control with pyrometer

- Cooling water recirculation unit

- Different vacuum systems

- Gas purging system

PRODUCT SPECIFICATIONS

Sizes

| Type | MFG-10 | MFG-20 | MFG-30 | MFG-50 | MFG-80 | MFG-100 |

|---|---|---|---|---|---|---|

| MF-Output power (kW) | 10 | 20 | 30 | 50 | 80 | 100 |

| Operating frequency, optimal range (kHz) | 10 – 100 | 8 – 100 | 8 – 100 | 8 – 80 | 5 – 70 | 3 – 70 |

| Mains supply | 3×400 V/50 Hz 12 kVA | 3×400 V/50 Hz 24 kVA | 3×400 V/50 Hz 36 kVA | 3×400 V/50 Hz 60 kVA | 3×400 V/50 Hz 96 kVA | 3×400 V/50 Hz 120 kVA |

| Cooling water (4-6 bar) | 10 l/min | 15 l/min | 20 l/min | 30 l/min | 50 l/min | 60 l/min |

| MF part dimensions (w x h x d) (mm) | 280x250x550 | 280x250x550 | 280x250x550 | 280x250x550 | 280x250x550 | 280x250x550 |

| Control unit dimensions *) (w x h x d) (mm) *) Compact unit has same dimensions | 520x1350x530 | 600x1900x500 | 600x1900x500 | 600x1900x500 | 800x1900x500 | 800x1900x500 |

| Weight control part /output adapter in kg | 60/5-20 | 120/10-30 | 130/10-30 | 180/20-50 | 260/25-60 | 300/30-70 |

| Compact unit in kg | 65-80 | 130-150 | 140-160 | 200-250 | 285-320 | 330-370 |

Technical details

Display elements (LCD display)

- Actual working power

- Working frequency

- DC current

- Heating time

- Fault indication

- Cooling water overtemperature

- Low cooling water flow

Control elements

- Main power switch

- START and STOP button

- Operational panel of the PLC Simatic S7

- RESET button

Security functions

- Cooling water flow protection

- Cooling water temperature protection

- Overload switch OFF – DC and MF current

- frequency limitation

Mains supply

The mains supply is realized over three fast semiconductor fuses.

Rectifier part

The rectifier consists of one three phase diode bridge, smoothing elements and one DC overcurrent limit circuit.

Converter part

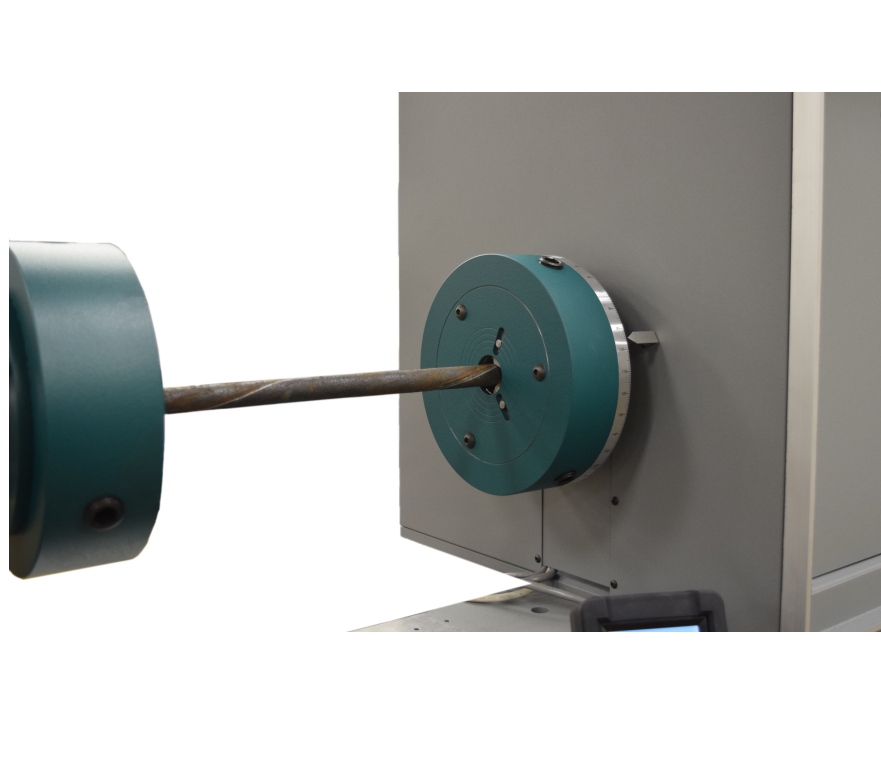

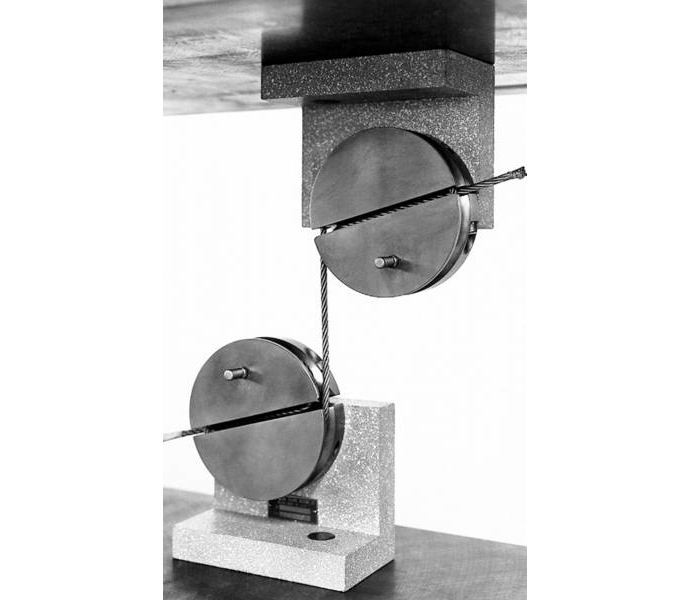

The converter part consists of the oscillator capacitors, IGBT modules, MF output connection and the control. The oscillator capacitors and the oscillator transformer are mounted in the separate adaptor frame and connected with the generator by the special flexible MF cable and cooling water pipes with the maximal length of 4 m. Upon the special customer request it is possible to integrate the output part in the generator frame.

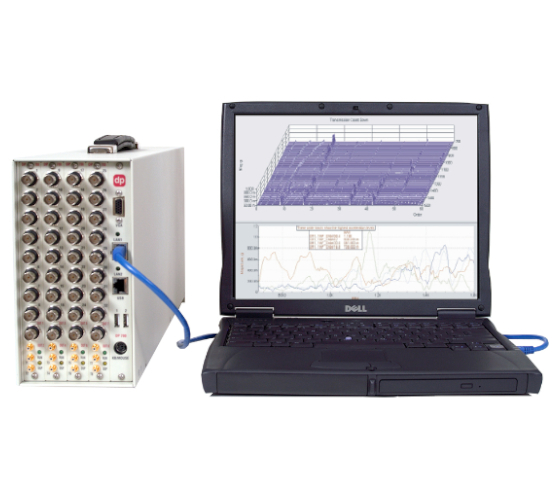

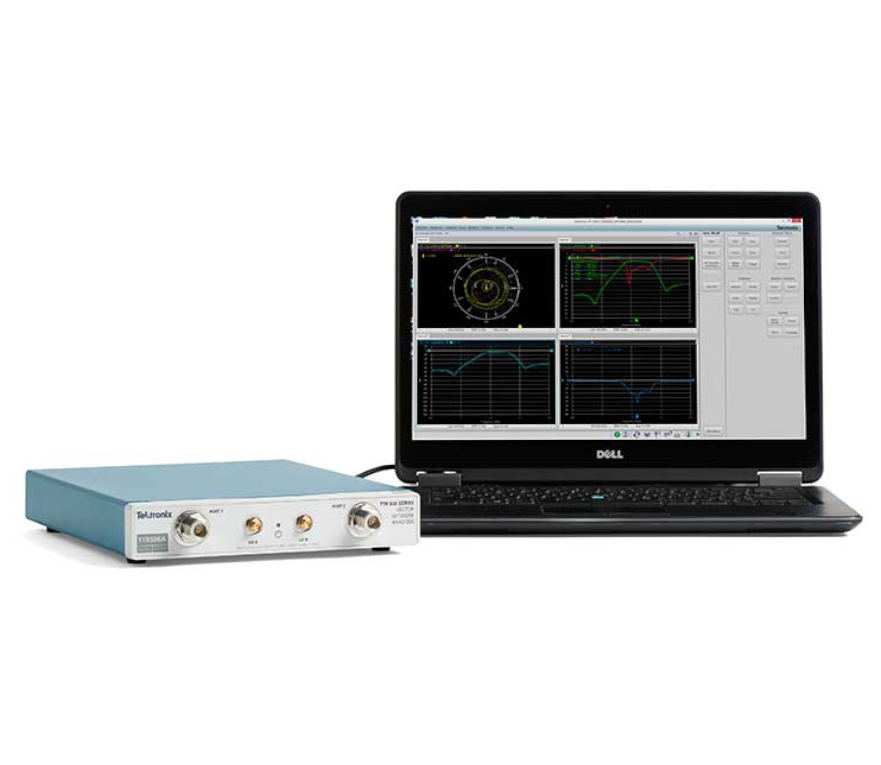

Control

The generator is completely controlled by the system Simatic S7 with touch screen. The operational panel is used for entering the working parameters and by that to control the equipment. Via the corresponding connector it is possible to operate the generator from remote devices. The important working data as well as the eventual faults will be displayed on the LCD display of the operational panel. As a special option we can offer the converter with two different working frequencies for the alternative work.

PRODUCT PROPERTIES

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch and Continuous |

| Construction Types: | Generator |

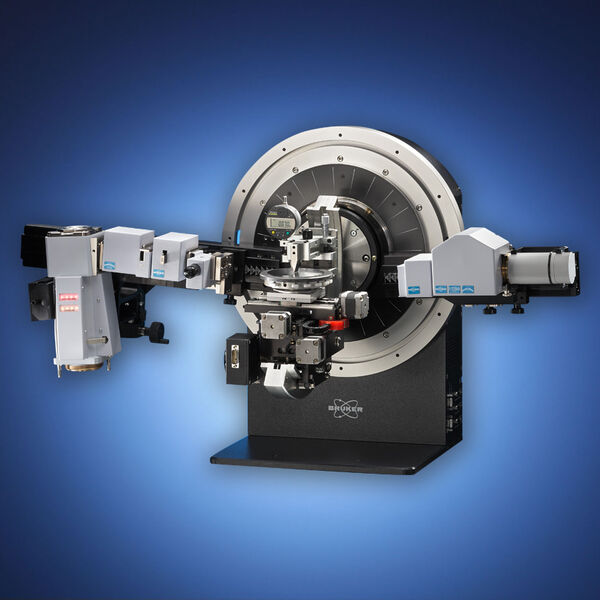

| Designs: | Crucible furnace, Fusion unit, Laboratory furnace, Remelting unit |

| Temperature Max (°C): | |

| Heatings: | electrical |

| Heatingmethods: | induction |

| Atmospheres: | Air, Controlled gas atmosphere, Overpressure, Vacuum |

| Applications: | activation, casting, crystal growing, CVD chemical vapour deposition, directional solidification, forging, gemstone heat treatment, glueing, graphitization/carbonisation, hardening, heat treatment, levitation melting, melting, pre-heating, pulling, remelting, sample preparation for spectroscopy, shrink fitting, soldering, stress-relieving, surface coating, tempering |

Reviews

There are no reviews yet.