Applications

Refineries

Norm-compliant sulfur analysis from Ultra-Low Sulfur (ULS) levels in diesel and gasoline up to high levels in crude oil according to international norms such as ASTM D7220, D4294 and ISO 13032.

With its multi-element capability the S2 POLAR is also well suited to measure Cl to minimize impact of corrosion, P against residue build-up, or to monitor catalyst elements in refinery processes.

Oils

Multi-element analysis of additives in lubricating oils is according to ASTM D6481 and D7751 including Mg, P, S, Cl, Ca, Zn, and Mo. Furthermore the S2 POLAR is also well suited to analyze elements in edible oils (e.g. Mg, P, Ca) or palm oils.

Technical Details

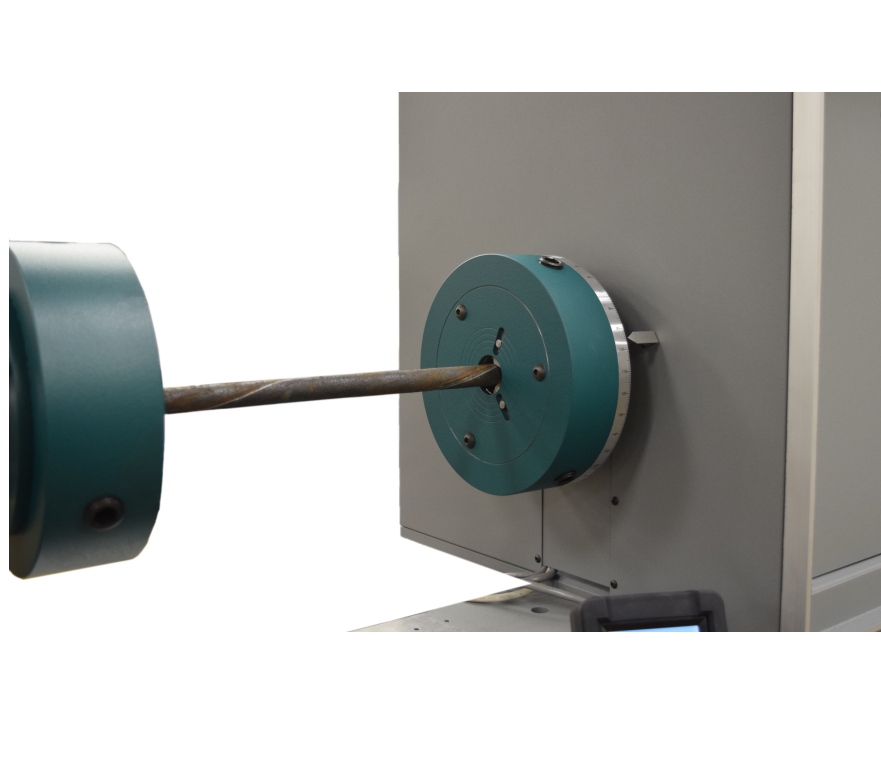

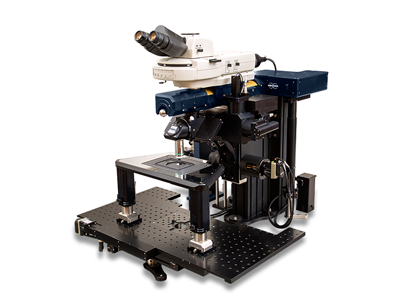

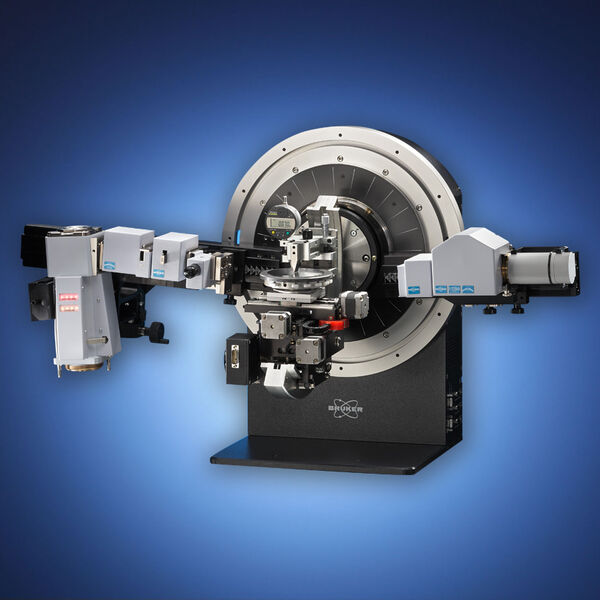

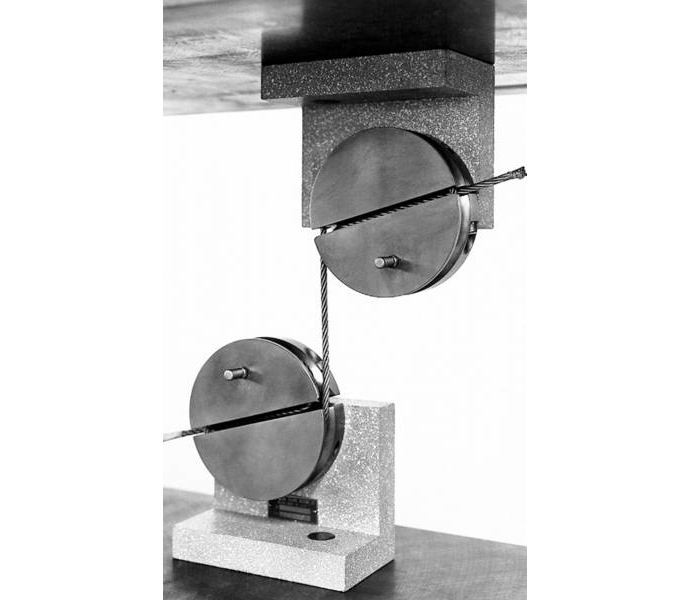

S2 POLAR Refinery Analyzer

| Specification | Benefit | ||

| Applications | Elemental analysis in refineries e.g. sulfur analysis of

Further elements on request (e. g. P, Cl, Fe, Ni, V) | All refinery applications on one unit | |

| Norms | ASTM D7220-17: Sulfur in automotive, heating, and jet fuels from 3 ppm to 942 ppm ASTM D4294-16: Sulfur in petroleum and petroleum products from 16 ppm to 5 % Ready-to-analyze solutions* for ASTM D7220 and D4294 including blanks, set of standards, QC and DC samples Fulfills ISO 13032, 20847, 8754, IP 336, 496, 532, and JIS K 2541-4 | Norm-compliant sulfur analysis, internationally accepted, including ultra-low sulfur (ULS) applications

Dedicated, optional pre-installed push button methods to fit for purpose | |

| Detection Limit (LLD) | 0.7 ppm S at 300 s measurement time | Precise and accurate S measurements, including ultra-low sulfur (ULS). Enables thesh-hold relevant process control at all steps in refineries | |

| Measurement Range | 3 ppm to 5 % S, combined in one calibration with automated line switch Higher concentrations on request | One calibration with wide concentration range |

S2 POLAR Oil Analyzer

| Specification | Benefit | ||

| Applications | Elemental analysis of additives in oils and polymers | Elemental analysis optimized for petrochemical products | |

| Norms | ASTM D6481-14: P, S, Ca, Zn, ASTM D7751-16: Mg, P, S, Cl, Ca, Zn, Mo Ready-to-analyze solutions* for ASTM D6481 and D7751 including blanks, set of standards, QC and DC samples Further elements and norms on request | Norm-compliant analysis, internationally accepted Dedicated, optional pre-installed push button methods to fit for purpose |

S2 POLAR Refinery & Oil Analyzer

| Specification | Benefit | ||

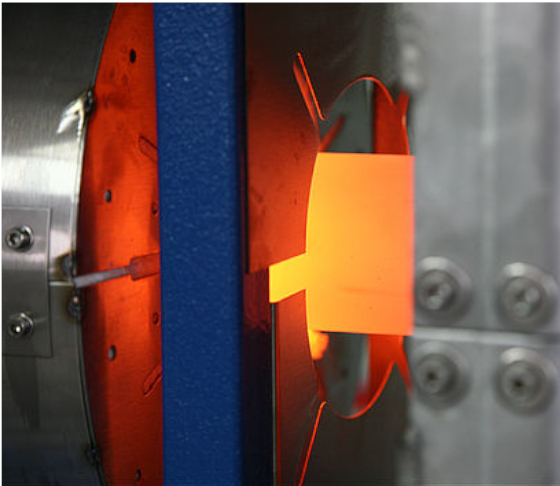

| Atmosphere Modes | Helium mode Vacuum mode | Optimal light element analysis of liquids Low cost of operation | |

| Sample Preparation | Liquid cups, SampleCare cups, Prolene and Mylar® foils, pipettes, balance | Accessories ensure high throughput of liquid samples. Low-cost per sample due to standardized liquid cups | |

| Further Options | Emergency Machine Off (EMO) Uninterruptible Power Supply (UPS) Sample rotation | Compliant with safety requirements Enables removing of liquid samples Enhanced precision for inhomogenous samples, such as polymer pucks | |

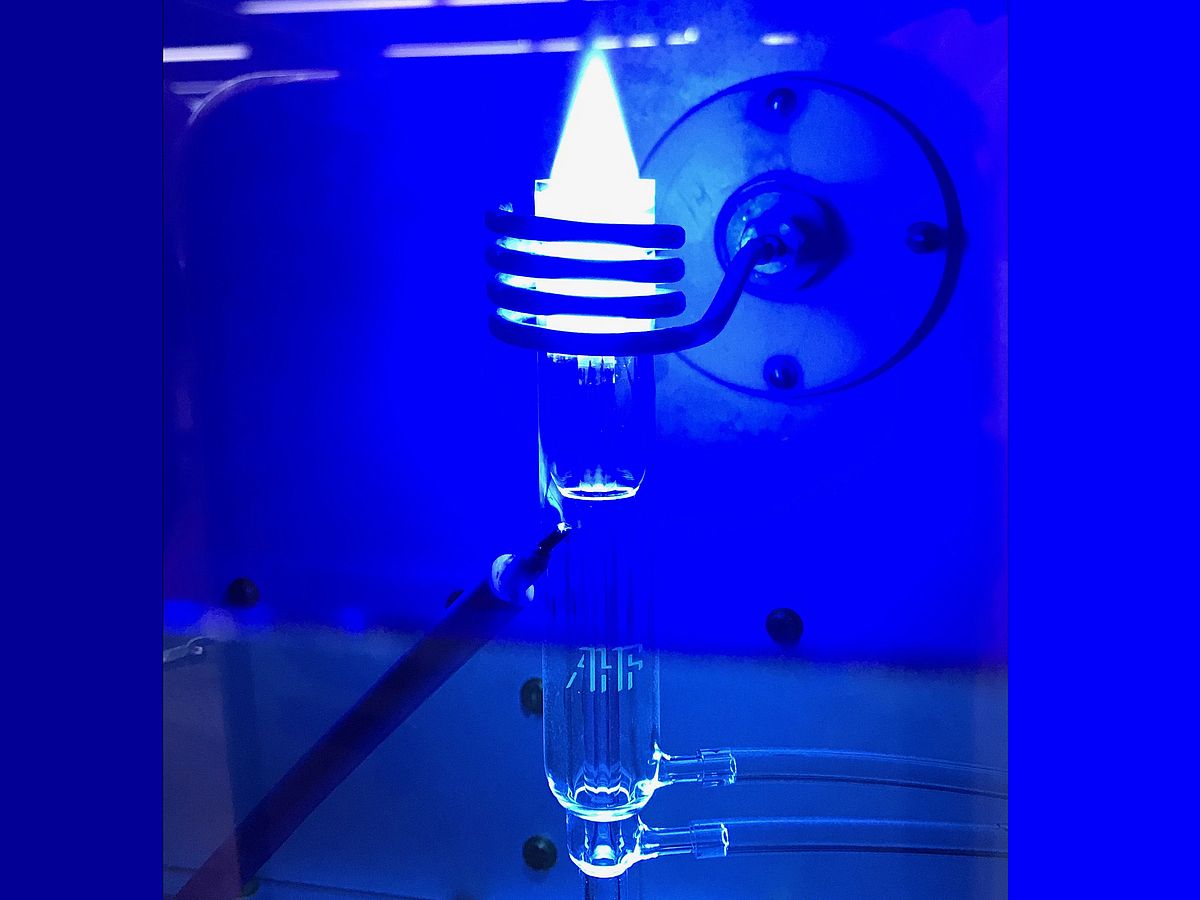

| X-ray Tube | 50 W, high-power X-ray tube, max. voltage 50 kV, with polarizing HighSense™ beam path Optionally: 30 kV max. | Max. power for short measurement times and high sample throughput, beam path optimized for petrochemical materials Simplify regulatory efforts (e.g. Austria, France, Italy, Taiwan) | |

| Detector | HighSense™ ULS Silicon Drift Detector | Highest count rates for fast analysis, low LLD | |

| TouchControl™ | Integrated 12.1‘‘ TFT touchscreen, multilingual user interface: English, German, French, Spanish, Portuguese, Italian, Russian, Chinese, Japanese | IslandMode™ without external PC Intuitive and easy-to-use, in your own language | |

| Connectivity | Ethernet port RJ45, 3x USB ports for mouse, keyboard, and printer; HDMI/VGA ports for external display, remote access via TCP/IP | IslandMode™ but not isolated, various options for printing and network data transfer, even fully remotely | |

| Power Supply | 100-240 V, 50/60 Hz, max. 600 VA | Standard wall plug | |

| Dimensions; width x depth x height, weight | 46.6 x 74.5 x 37.0 cm, 55 kg 18.3’’ x 29.3’’ x 14.6’’, 121 lbs | Small and compact for installations with limited space, e.g. for on-site process control in refineries |

| Safety

| DIN EN ISO 9001:2008, 2006/42/EC (CE-certified Machinery directive), 2014/35/EC (Electrical equipment), 2014/30/EC (Electromagnetic Compatibility), German Type Approval and Vollschutz according to BfS RöV, Fully radiation-protected system; radiation <1 μSv/h (H*), Compliant to ICRP, IAEA, EURATOM |

* Optional packages

Mylar® is a trademark of DuPont Nemours Inc.

HighSense™, IslandMode™, SampleCare™, TouchControl™ are trademarks of Bruker AXS.

Reviews

There are no reviews yet.