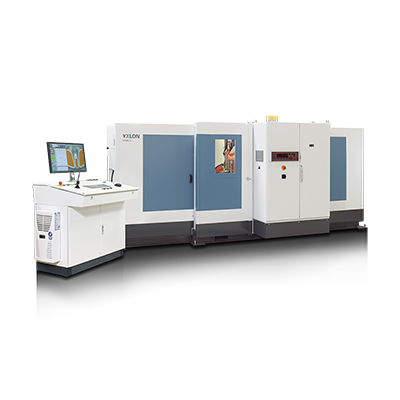

System Capabilities

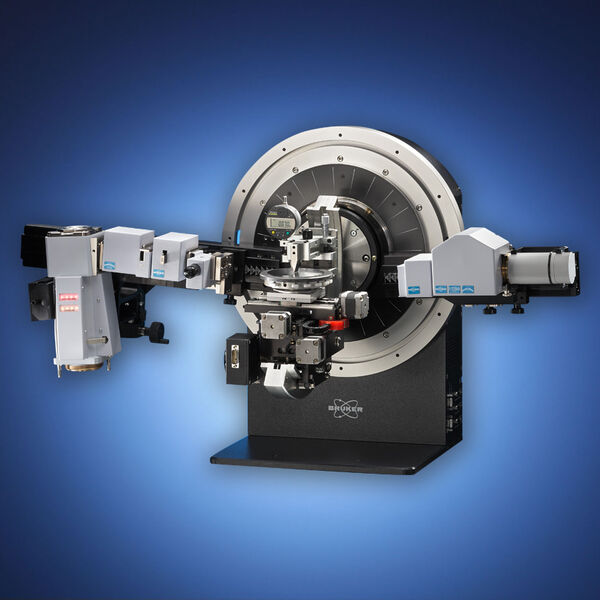

WI26 G is our most advanced inline wheel X-ray inspection system for alloy wheels, combining high-speed wheel inspection and outstanding image quality. The WI26 G is dedicated to automatic inspection with software that delivers objective and reliable decisions and a minimum of pseudo rejects.

The system has been designed for maximum availability in 24/7 inline operation and minimum cost of ownership due to low maintenance requirements.

WI26 G offers short cycle times for your whole product mix:

- Less than 20 seconds for inspection of an example 7×17″ wheel with 5 spokes (that’s nearly 1.5M wheels per year) or

- A short 22 sec cycle time for a 8×19″ wheel with 7 spokes.

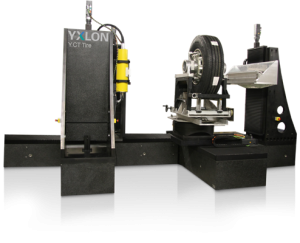

New gripper manipulator technology supports a range of 13‘‘ to 26‘‘ size wheels with a maximum width of 430 mm and a weight of up to 50 kg. And our state-of-the-art YXLON Panel 460 detector offers the best image quality with 16 bit dynamic resolution and a large active area of 300 mm x 300 mm, which saves inspection time due to a minimum number of necessary projections.

New revolving lock system allows quick and smooth in/out feed of wheels at high throughput with a minimum of wear on parts.

WI26 G features a small footprint with wide opening service access doors and can be fully integrated in your wheel plant processes:

- Casting station delivers the X-ray results straight to the casting for fast feedback new batches

- Statistics server delivers data for continuous improvement of the production quality

- Review station allows maximizing the inspection efficiency

Technical Data

| Attribute | Respective Value |

|---|---|

| Sample Dimensions | Diameter: 660 mm max. Overall width: 430 mm max. |

| Maximum Sample Weight | 50 [kg] |

| System Dimension | 4840 x 2340 x 2150 [mm] |

| X-ray Tube | 160 kV / 1000 W |

| Detector Active Area | 300 x 300 [mm] |

| Pixel Pitch | 200 [µm] |

| Bit Depth | 16 [bit] |

| Cycle Time | 20 s for example 7J x 17″ wheel |

Đánh giá

Chưa có đánh giá nào.