Options

- Serial interface

- Separately controlled heating

- Movable bottom

- Useful room temperature for short time 1400°C for KK-750 and bigger

- 1280°C low cost version

- Multifunctional unit

- Supervision of temperature progress by display recorder

- Underframe

- Insert plate made of cordierite

- Pot support

PRODUCT SPECIFICATIONS

Sizes

| model | liters | inside dimensions mm (wxdxh) | in °C | heating power kW |

|---|---|---|---|---|

| KK-55 | 55 | 320 x 450 x 380 | 1300 | 3,3 |

| KK-80 | 77 | 400 x 400 x 480 | 1340 | 7,5 |

| KK-120 | 125 | 460 x 460 x 590 | 1340 | 9,6 |

| KK-170 | 166 | 460 x 610 x 590 | 1340 | 12,0 |

| KK-220 | 220 | 610 x 610 x 590 | 1340 | 15,0 |

| KK-260 | 260 | 610 x 610 x 700 | 1340 | 18,0 |

| KK-350 | 351 | 610 x 720 x 800 | 1340 | 21,0 |

| KK-500 | 505 | 610 x 920 x 900 | 1340 | 25,0 |

| KK-750 | 750 | 740 x 920 x 1100 | 1340 | 48,0 |

| KK-1000 | 900 | 850 x 970 x 1090 | 1340 | 60,0 |

| KK-2000 | 1750 | 850 x 1880 x 1090 | 1340 | 100,0 |

Technical details

Furnace housing

The furnace housing consists of a lightweight steel construction. As protection against corrosion they are coated with a special lacquer. The chosen colors blue/white give a nice appearance to the entire furnace.

Insulation

Ceiling, heated side walls, rear wall and bottom are covered with high quality lightweight refractory bricks. By using these bricks the burning goods will not be contaminated by broken insulation material falling down.

The additional heat insulation with calcium silicate boards ensures a high thermal capacity at low energy consumption. The door is lined with fiber modules.

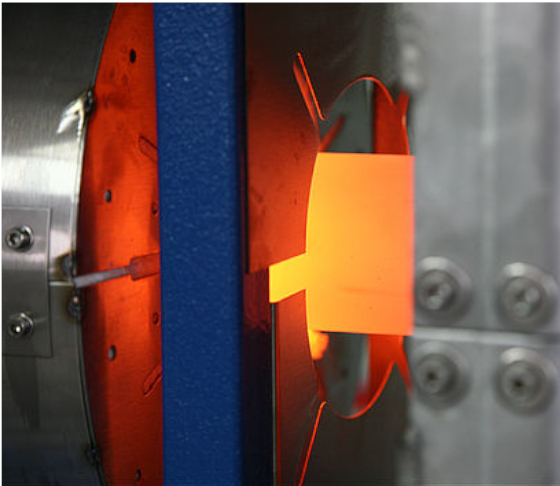

Heating

Heating is effected by free radiating Kanthal A1 bzw. APM heating spirals (hair pins) in rills of the bricks of the side walls, the rear side and the bottom. The furnace bottom is covered with a well thermal conductive ceramic plate. For the activation of the waste of the burning materials and the cooling behavior during cooling phase, air channels are installed in the furnace bottom through which fresh air with well chamber distribution will be guided to the top side due to thermal lifting.

Control unit

Connection field and power electronic are tightly installed at the furnace rear side. The controller G800 is placed in a separate housing which is connected to the furnace and is assembled at the side wall of the furnace system:

- 2 or 3 setpoint controller with PID behaviour

- Logic output and continuous output

- Max. 4 programs with max. 16 segments / steps programmable

- Display of actual and desired value

- Self-optimization prevents overshooting

- Separation of control and configuration level (prevents undesired changes)

- 4 switchable parameter sets

- Alarm signal in case of thermocouple fracture

- Serial interface

A safety switch is installed on the furnace which switches off the heating during opening the door by a constraint disconnection. The furnace is provided with a connection cord.

PRODUCT PROPERTIES

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Furnace |

| Designs: | Chamber furnace |

| Temperature Max (°C): | 1340 |

| Heatings: | electrical |

| Heatingmethods: | resistance |

| Atmospheres: | Air |

| Applications: | ashing, calcination, debinding, firing, fusion, oxydation, pre-heating, shrink fitting, stress-relieving |

Reviews

There are no reviews yet.