Options

- Service cable to pyrometer

- Program-Terminal KPT 300

- PC-Universal Interface (USB) KUI

- Circulation cooling unit RK-3

- Circulation cooling unit RK-4

- Service cable 342

PRODUCT SPECIFICATIONS

Sizes

| Model | Outside dimensions mm (B x T x H) | HF max. kW | max. Sample weight | max. Sample size |

|---|---|---|---|---|

| C-3.3T | 985 x 680 x 1530 | 3,3 | Oxyd.: 15 g Met.: 80 g | Ø 40mm |

| C-3.3T-Vac | 985 x 680 x 1530 | 3,3 | Oxyd.: 15 g Met.: 80 g | Ø 40mm |

Technical Data

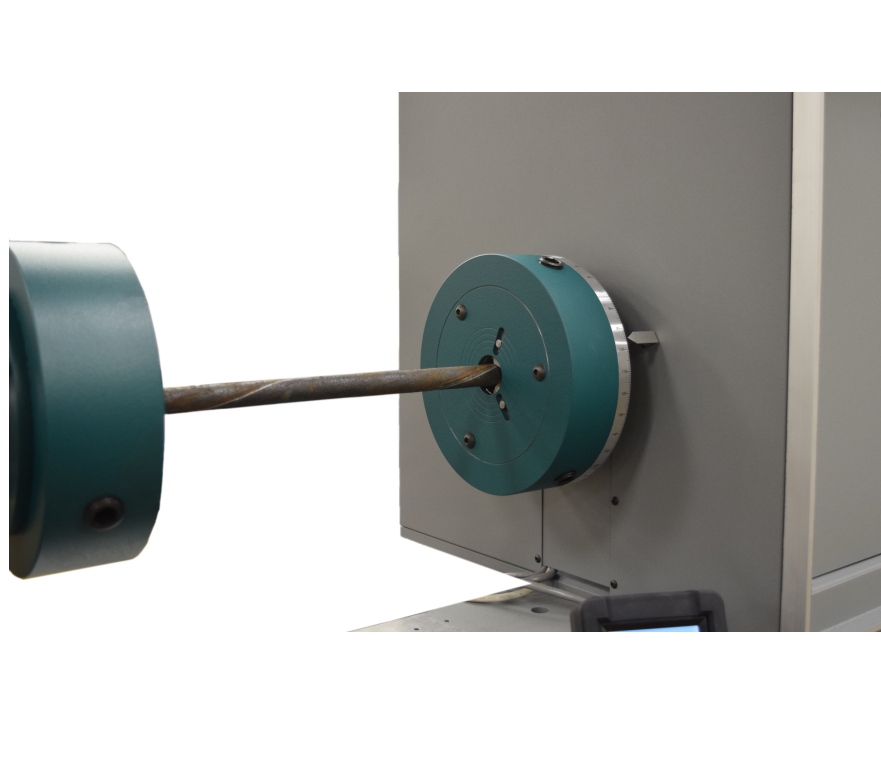

Remelting Unit

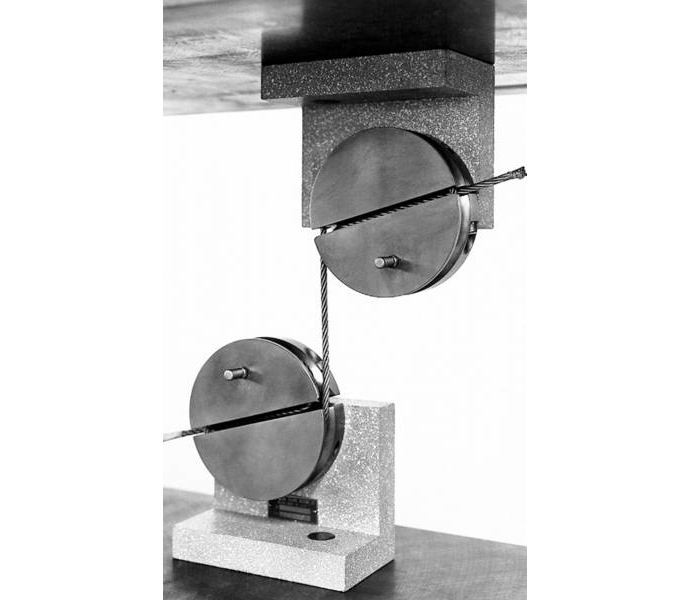

The machine will be used for preparation of metallic spectrometer samples with uniform composition for the emission or X-Ray spectral analysis. It consists of a 1,5 MHz, fitted with noise suppression, high frequency generator with output power of 3,3 kW which is mounted together with the under protective gas and optionally under vacuum working induction melting furnace and centrifugal casting device in a compact housing. The required space is appr. 1,0 m².

Fusion unit

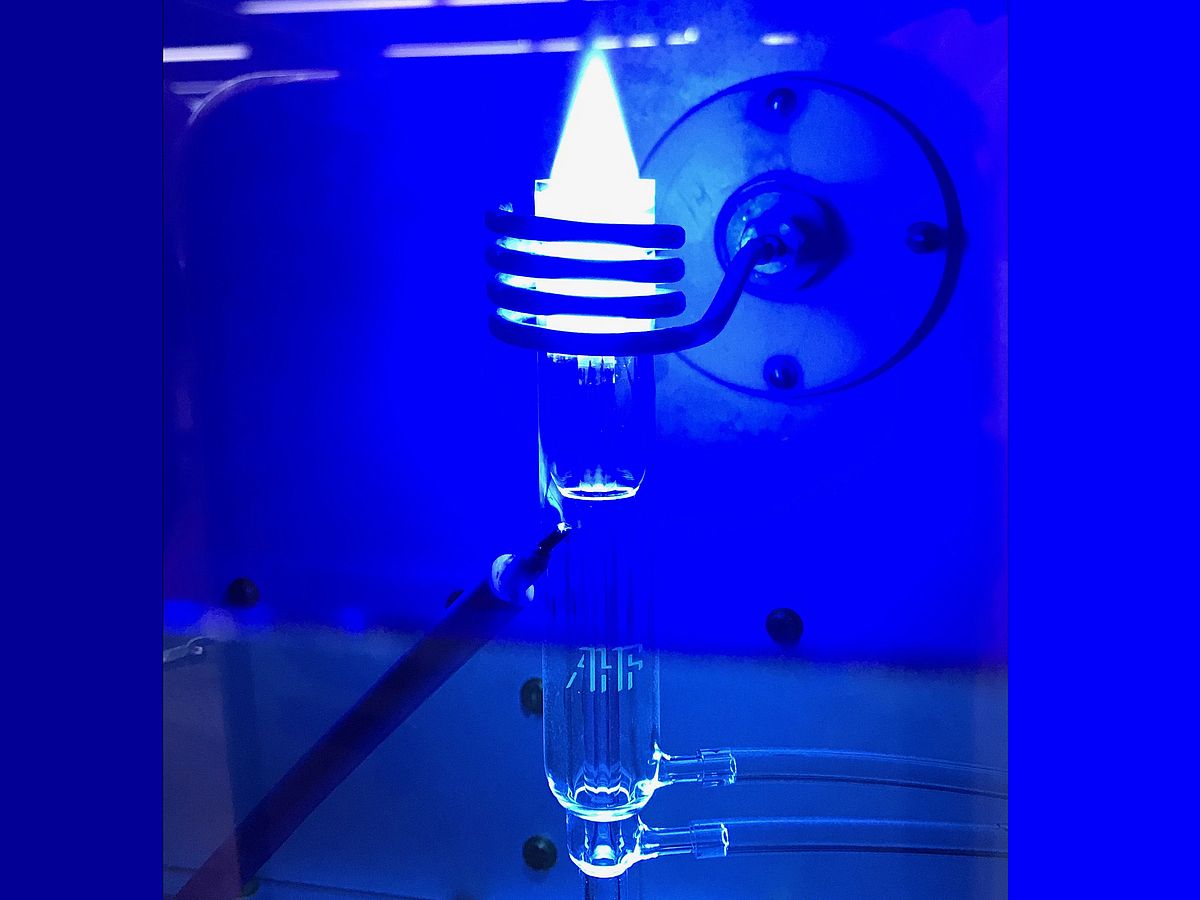

- Melting coil for absorption of a fusion crucible (Pt/Au, glass carbon, graphite, met. zirkon) which is located in a ceramic crucible

- Preheating coil for casting dish

- Vibration installation for better homogenisation and avoiding of air locks

- Temporary programming of vibration installations with programme controller

- Shelves for fast cooling of the samples

Application Fusion Unit

Fast sample preparation for X-Ray fluorescence analysis (RAF), ICP and AAS. Melting of small oxidic samples.

Melt fusion of oxidic materials, f.ex. ores, slag, dust, minerals, refractory materials etc. in a special platinum/gold crucible (95/5%) or glass carbon crucible under use of lithium tetraborate or natrium carbonate.

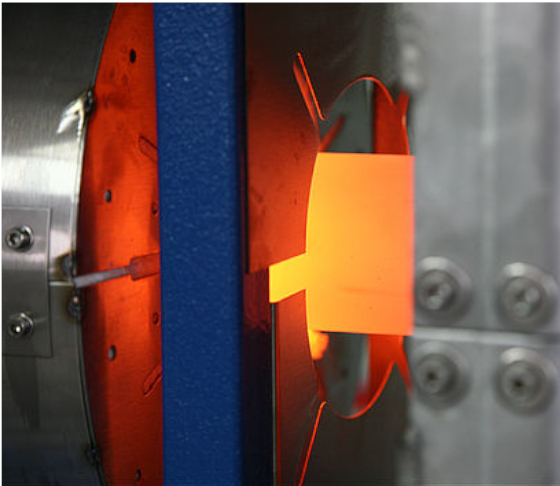

The fusion material which is located in the crucible will be melted through induction heating. Ponderomotive forces, which effect a bath movement and thus ensure a uniform material distribution, arise through the stray field. Depending on material quality temperatures up to appr. 1500°C can be run. The stirring will be supported through a motor vibrator which can be selectively switched on. The casting dish will simultaneously with the crucible be inductively preheated through a double induction coil. The temperature will, in automatic operation, be supervised through a pyrometer.

Construction

The HF generator with protection cover, which is installed in a solid built sheet steel housing, corresponds to the aspects of modern working protection and CE guidelines.

The melting process can be well observed over a blue glass that is integrated in the cover. The induction coil is easily changeable. When opening of the housing cover, the power will be switched off automatically. A fan evacuates to the back side the inner chamber of both melting units for protection of operating staff.

Machine Control

Hardware

The operation is effected through a 7“ colour-Touchpanel with 10 integrated function keys and integrated SPS function. Local components are used for control of machine functions.

All inlet and outlets of the sensors and actuators are galvanically separated and MF/HF is fail-safe connected with the local control unit.

The process datas and parameters can be read out over an USB interface.

A well accessible emergency switch off offers additional safety in operation.

Function volume

The self explanatory menu navigation and guided programme processes make a simple operation possible. The optical display of the programme process and the respective working steps inform about the current state of the machine. With integrated recipe administration for the melting programmes. The written melting programmes can be saved on a USB storage medium and levelled to all further machines of same Lifumat type, without having to compile it new.

The safety supervision of diverse functions will be effected with clear text alarm like f.ex. cooling water temperature, cooling water flow, cover and door locking, generator stream (power). Optical and acoustical signal will be effected in case of disruption and casting process end.

The operator language is free selectable in German and English (further against surcharge).

The user levels (producer, administrator, operator) are locked.

Manual Function

In order to optimize processes and compiled melting programmes, the process parameters are free changeable. With status display of hardware inlet and outlet.

PRODUCT PROPERTIES

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Casting unit, Melting unit, Sample preparation unit |

| Designs: | Fusion unit, Precision fine casting system, Remelting unit |

| Temperature Max (°C): | 1500 |

| Heatings: | electrical |

| Heatingmethods: | induction |

| Atmospheres: | |

| Applications: | casting, fusion, melting, remelting, sample preparation for spectroscopy |

Reviews

There are no reviews yet.