Options

- Different controller systems

- Supervision of temperature progress by display recorder

PRODUCT SPECIFICATIONS

Sizes

| Type | Liter | Inner dimensions mm (wxdxh) | Quantity floors | Floor height mm | Heating power kW |

|---|---|---|---|---|---|

| KK-DH 80 | 80 | 400 x 400 x 480 | 2 | 200 | 7,5 |

| KK-DH 170 | 170 | 460 x 610 x 590 | 2 | 250 | 15 |

| KK-DH 260 | 260 | 610 x 610 x 700 | 2 | 300 | 18 |

| KK-DH 1000 | 1060 | 1000 x 1000 x 1060 | 3 | 300 | 43 |

The following table reflects guide values for charging with casting moulds, cuvettes or similar.

| Type | Liter | Quantity (moulds, cuvettes) | Diameter mm |

|---|---|---|---|

| KK-DH 80 | 80 | 16 | 90 |

| KK-DH 80 | 80 | 14 | 100 |

| KK-DH 170 | 170 | 38 | 80 |

| KK-DH 170 | 170 | 14 | 120 |

| KK-DH 260 | 260 | 52 | 80 |

| KK-DH 260 | 260 | 36 | 100 |

| KK-DH 1000 | 1060 | 18 | 150 |

| KK-DH 1000 | 1060 | 12 | 180 |

Technical details

Furnace housing

The furnace housing consists of a lightweight steel construction. As protection against corrosion they are coated with a special lacquer. The chosen colors blue/ white give a nice appearance to the entire furnace.

Insulation

Due to the light-brick lining and fibre insulation of the furnace chamber as well as the door which is lined with ceramic fibre material, low connection values and short heating-up cycles up to the maximum temperature of 1050 °C are possible. In the furnace ceiling there are, depending on the furnace size, one or several ventilation sockets for connection of an exhaust system or a afterburning.

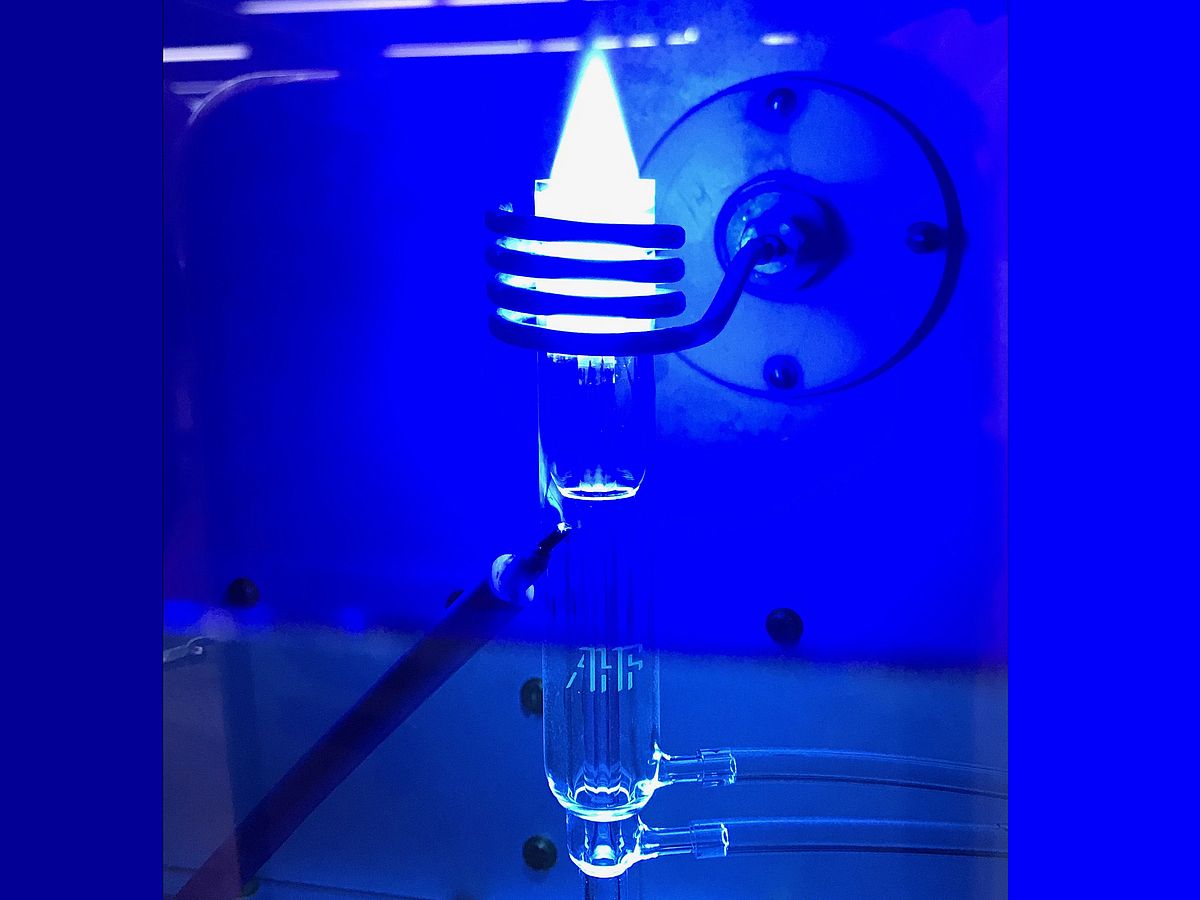

Heating

The heating spirals made of high-quality FeCrAl alloys are placed in both sidewalls, the rear wall and in the bottom of the furnace. Opening of the door during heating is prevented by a compulsory limit switch. The door locking is mounted undetachably.

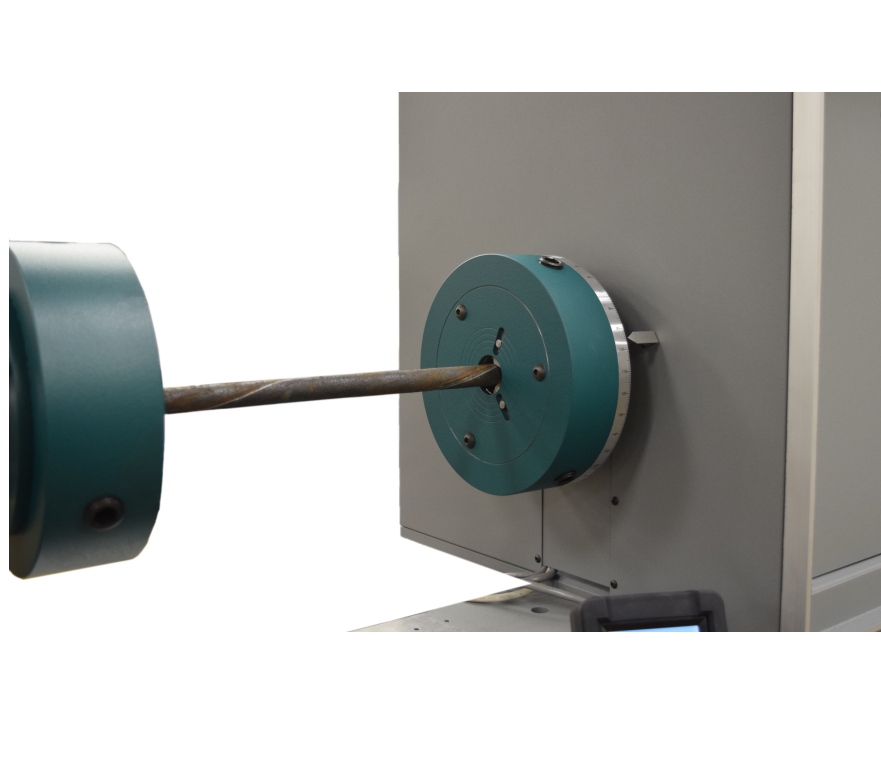

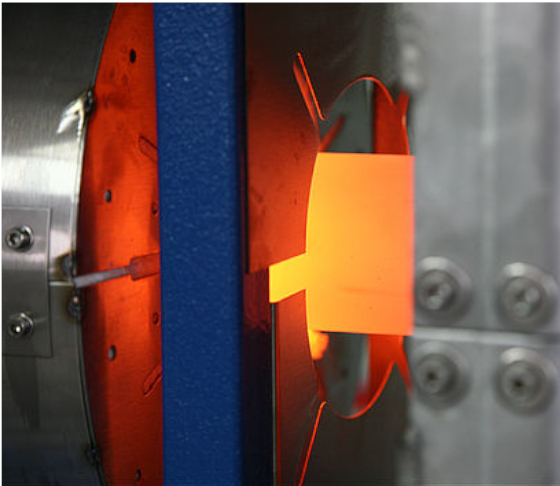

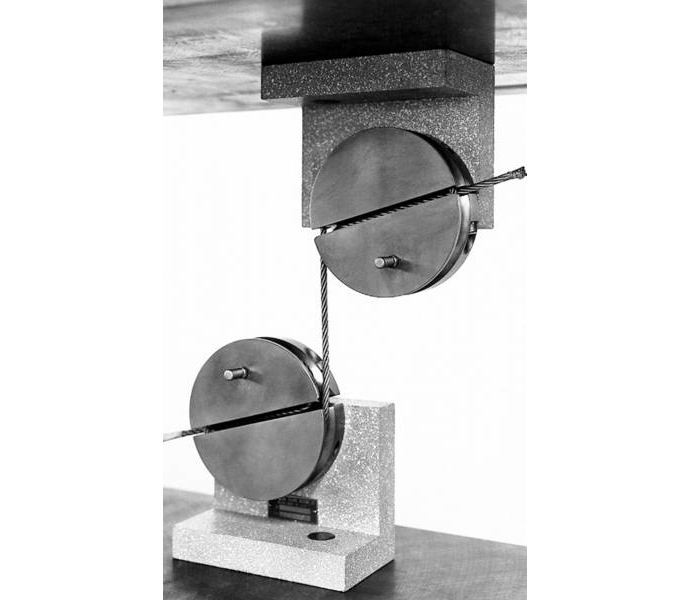

Rotary disk device

Rotary disks of heat resistant steel (Mat. No. 1.4841) are mounted on a shaft with distance of the corresponding floor height. The shaft gets through the bottom insulation and thereby is mounted in the underframe. Through the hollow shaft an additional ventilation of the furnace room is realized. The drive is carried out by a three-phase current synchronous motor, which is also positioned in the underframe, via a toothed belt. For charging the furnace a foot switch is intended on the charging side, which enables the rotary disk to clock at charging operation. The loading and removal doors are opened by hand.

On the lower end of the shaft there is a removable collecting vessel for wax.

Control unit

The temperature control is done via a NiCrNi-double thermocouple (accuracy class 2 according to DIN IEC 584 part 2) with compensating cable with the following described program controller type G 800:

- 2 or 3 setpoint controller with PID behaviour

- Logic output and continuous output

- Max. 4 programs with max. 16 segments / steps programmable

- Display of actual and desired value

- Self-optimization prevents overshooting

- Separation of control and configuration level (prevents undesired changes)

- 4 switchable parameter sets

- Alarm signal in case of thermocouple fracture

- Serial interface RS 485 as option (not upgradable)

Further components are main switch, fuse operating hours counter, safety controller as well as adjustment of the rotation speed.

PRODUCT PROPERTIES

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Furnace |

| Designs: | Chamber furnace |

| Temperature Max (°C): | 1100 |

| Heatings: | electrical |

| Heatingmethods: | resistance |

| Atmospheres: | Air |

| Applications: | dewaxing, firing, pre-heating |

Reviews

There are no reviews yet.